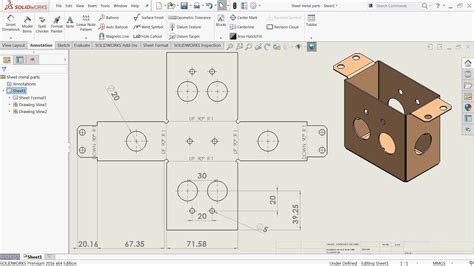

solidworks complex sheet metal Learn how to make a complex sheet metal part using Sketched Bends and Edge Flanges with the Part Reviewer Tool in SOLIDWORKS!

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

0 · solidworks sheet metal template

1 · solidworks sheet metal examples

2 · solidworks sheet metal download

3 · solidworks sheet metal cut list

4 · solidworks sheet metal basics

5 · sheet metal solidworks pdf

6 · sheet metal modeling in solidworks

7 · sheet metal in solidworks 2021

I have a junction table (ProjectGrant) with two primary keys (ProjectID) and (GrantID), one from each table, which creates a many to many relationship. I am trying to add .

solidworks sheet metal template

SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create complex sheet metal designs. Multibody sheet metal parts can consist of multiple sheet metal . How To Model Complex Sheet Metal Parts in SOLIDWORKS. A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved . Complex sheet metal components can be modelled easily by modelling the volume or the outside shape of the finished component and then using the Convert to Sh. When most people think of sheet metal in SOLIDWORKS, they think of brackets, covers, and enclosures. These “traditional” sheet metal designs lend themselves well to a .

SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of . Learn how to make a complex sheet metal part using Sketched Bends and Edge Flanges with the Part Reviewer Tool in SOLIDWORKS! The Solidworks Sheetmetal Design and Developments software is a powerful tool for designing and developing sheet metal products with ease and precision. Whether you are creating simple brackets or complex enclosures, .

Download: Complex Sheet Metal Part 6. Complexity: Complex. Features: Base Flange, Edge Flange, Sketched Bend, Mirror Feature, Cutouts. View all the Part Reviewer Tutorials here.SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create complex sheet metal designs. Using Sheet Metal Bend Parameters. Glossary. Comparing . SolidWorks offers an array of specialized features to develop complex sheet metal assemblies. For example, the sheet metal module in SolidWorks offers tricks, shortcuts, and automatic commands to create .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody . Complex Sheetmetal Part 5: This feature distinguishes that this is a sheet metal part. It specifies the bend radius, wall thickness and K factor. This part is created using sheet metal features so that the part can be flattened out . Complex Sheet Metal Part 6: Sheet metal features are used so that the part can be flattened out to create a flat pattern. Menu Toggle navigation. SOLIDWORKS Blog; . Dassault Systèmes SolidWorks Corp. offers complete 3D software tools that let you create, simulate, publish, and manage your data. SolidWorks products are easy to learn and use .

The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Good afternoon¡¡¡ I have a problem with this part attached. I can´t have the flat pattern of this sheet metal. I work with 2009. If someone could help me i will be very gratefull. thanks¡ . complex sheet metal. CN By Carlos Navarro 05/09/12.SOLIDWORKS Sheet Metal Overview. The SOLIDWORKS Sheet Metal course is designed for users who need to learn how to model sheet metal parts that will be manufactured using a variety of forming processes. You will learn how to build complex sheet metal models (standalone or multibody) by using the various flange features, or converting solid .

I ran through this very quick, and messed up my terminology between transverse and longitudinal, but hopefully it will still be helpful.See more about our pr.

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

Complex Sheet Metal Part 6: Sheet metal features are used so that the part can be flattened out to create a flat pattern. A closed corner adds. . Dassault Systèmes SolidWorks Corp. offers complete 3D software tools that let you create, simulate, publish, and manage your data. SolidWorks products are easy to learn and use, and work together .

With sketch-based forming tools, you can create a sketch with a few parameters to stamp or form the sheet metal. Normal Cut in Tab and Slot. When you use the Tab and Slot tool, you can specify that the slot is normal to the sheet even if the tab is at an angle to the slot. Slots that are normal to are essential in the manufacturing process. CATI's monthly contribution to the SOLIDWORKS Blog was posted this week. This month I chose to write about how to flatten complex sheet metal parts with SOLIDWORKS Lofted Bends. The article is based upon some common questions that we get from customers. The article has a detailed example of how we can build a model [.]Convert to sheet metal - bend too complex . CAD . I'm want to develop a flat pattern for this in sheet metal, but after doing 'collect bends' and clicking ok to convert to sheet metal, I am getting the warning: "The geometry in the bend region is too complex". . If you have SOLIDWORKS Premium you can use the Surface Fatten tool (GoEngineer . Complex Sheet Metal Part 3: Sheet metal features are used so that the part can be flattened out to create a flat pattern. The base flange was built it flat state to ensure correct footprint. . Dassault Systèmes SolidWorks Corp. offers complete 3D software tools that let you create, simulate, publish, and manage your data. SolidWorks products .

2) Best Approach To Modeling Sheet Metal Bodies SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of geometries, the user has the option to use non-sheet metal feature tools and then use the

solidworks sheet metal examples

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create complex sheet metal designs. Multibody sheet metal parts can consist of multiple sheet metal bodies or a combination of sheet metal and other bodies such as weldment bodies. . Search 'Multibody Sheet Metal Parts' in the SOLIDWORKS Knowledge Base.

Stp files don't include the necessary information to convey that it is a sheet metal part. When you make sheet metal parts in OnShape or Solidworks, more information than just the 3D model is being created and processed. It's how these programs know that a bend is impossible or how to unfold. You need a more descriptive file or remake the model.SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create complex sheet metal designs. Multibody sheet metal parts can consist of multiple sheet metal bodies or a combination of sheet metal and other bodies such as weldment bodies. . Search 'Multibody Sheet Metal Parts' in the SOLIDWORKS Knowledge Base. Sheet Metal Design: SolidWorks makes it easier to design sheet metal parts like enclosures and brackets, allowing users to make accurate bends, cuts, and patterns. Assembly Design: Complex assemblies can be created by combining parts. Designers can check for proper fit, alignment, and function to find any potential problems.2) Best Approach To Modeling Sheet Metal Bodies SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of geometries, the user has the option to use non-sheet metal feature tools and then use the

Similarly, those tricky miters are equally complex and most designers often struggle to manage them in 2D, which eventually leads to loss of time and money. Say Goodbye to the Gaping Woes: SolidWorks animation makes the task easy. Using the Miter flange command, design experts effortlessly tackle complex miters in sheet metal designs. 3.0.2 How does SOLIDWORKS help in designing complex sheet metal parts at Approved Sheet Metal? . Start by centering your SolidWorks sheet metal design: When beginning your design, place the part's center right in the middle of the design area. This approach provides more flexibility and freedom from the start, and it can prevent rework in .In that case the geometry is somehow too complex in that cut region for SOLIDWORKS to pick it up as a simple cut. I would probably remove the cut and re-apply it manually after it is converted to sheet metal. To do that, you can use Delete Face to delete and patch or extrude the material across the gap.

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody . Catalog. View in SOLIDWORKS User Forum View on Forum . Use your 3DEXPERIENCE ID to log in. Preview | SOLIDWORKS USER FORUM Complex sheet metal. Can anyone do this? The competition begins. IO By Ivan O'Blak 09/24/20. answers: 12 . ©2002-2024 Dassault Systemes SolidWorks Corporation .Use your SOLIDWORKS ID or 3DEXPERIENCE ID to log in. . Forming complex sheet metal. VC By VINCENT COLLIN 09/10/24. Soo, ive been trying for hours to make this work but it just dont. So basicly i have to make this part into a 5/8" thick sheet metal with 5/8" bend radius, it was working earlier until i had to make the part longer. .

Leverage SolidWorks flexibility for complex sheet metal shapes The CAD designer or the engineer might not have the opportunity to start with the sheet metal module every time. In this scenario, one can start with the free form concepts of 3D solid models and surface creation.

range junction box

Precision in Orthodontic Treatment: The Gemini Metal Twin Bracket Design ensures precise and reliable orthodontic treatment. Orthodontic professionals can trust these brackets for accurate .

solidworks complex sheet metal|solidworks sheet metal basics