solarlok 1-rail junction box SOLARLOK 1-rail junction box, designed both for thin-film and BiPV potting applications, allows you to decentralize the two leads in separate locations on the back of the module. You can weld something with a soldering iron by using it to melt solder between sheets of metal and allowing it to harden, creating a bonded joint. However, while soldering and welding are terminologies used interchangeably, there is a difference between the two processes.

0 · TE SOLARLOK Junction Boxes

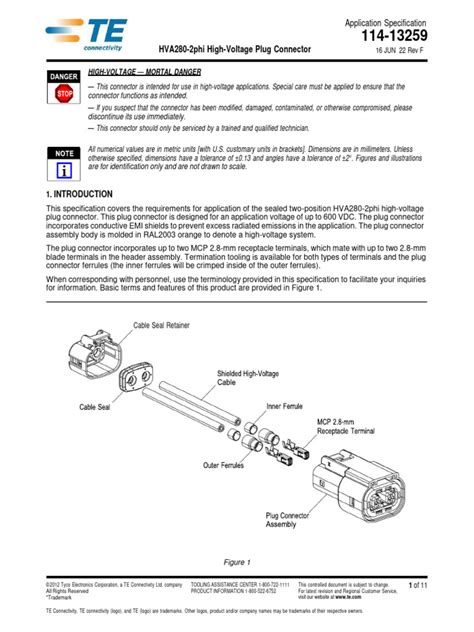

1 · SOLARLOK* Application Specification 114

2 · SOLARLOK 1 Rail Junction Box System

3 · Introducing SOLARLOK 1

4 · Class 1 Document

Founded in 1981, Western Bay Sheet Metal, Inc. remains a family-owned company that has become one of San Diego County’s leading architectural and general sheet metal, architectural metal, composite panel (ACM) and ornamental and decorative metal fabricator and installer.

TE SOLARLOK Junction Boxes

SOLARLOK 1-rail junction box, designed both for thin-film and BiPV potting applications, allows you to decentralize the two leads in separate locations on the back of the module.

SOLARLOK 1 Rail Junction Box used for distributing energy captured by solar panels used in the Photovoltaic (PV) industry. The one set consists of two type connection boxes, non- diode type .This specification covers the performance, tests and quality standards for the SOLARLOK* Z-Rail Junction box which allows the electrical connection between Photovoltaic (PV) panels. The .The SOLARLOK 1-rail junction box is now available in a non-potted version. This new 1-rail product is designed to eliminate the need for potting 1-rail junction boxes.

blum stainless steel drawer boxes

SOLARLOK* Application Specification 114

This specification covers the requirements for application of SOLARLOK PV Edge Solar Junction Box onto a photovoltaic (PV) solar panel. Each junction box consists of a base (with or without .

With 3 sizes of junction boxes, up to six contact termination rails are available for photovoltaic foil connection. SOLARLOK Junction Box Features Integrated and Sealed One-Component .SOLARLOK Z-Rail Junction Boxes 411-18305-1 SOLARLOK Interconnect System 411-137003 4 IN 1 tool for Z-rail Omega foil-clip installation 114-137077 PV4-S application specification . 114-13303-1 Rev.E1 3 of 18 3. REQUIREMENTS 3.1. Safety — Appropriate gloves and eye protection must be used throughout the entire installation of the junction box. .The SOLARLOK 1-rail junction box is now available in a non-potted version. This new 1-rail product is designed to eliminate the need for potting 1-rail junction boxes. The product is available in a no diode version and a blocking diode version. The assembly comes with a small junction box, dual rated TE solar cable and our SOLARLOK connector .produces a 100% automatically inspected and electrically tested junction box. For quality control purposes, each junction jox is “laser etched” with a unique serial number. Our electrical test equipment has four independent heads to automatically test each connection rail and diode in the popular four rail junction box. Assembly equipment

connection rail and diode in the popular four rail junction box. Assembly equipment automatically verifies the production of the cable assemblies and attachment to the junction

114-32157: Application Specification (SOLARLOK* PV Edge Solar Junction Box Assemblies) 404-74000-1: Model Code for SOLARLOK* System 501-134079: Qualification Test Report (SOLARLOK* PV Edge Solar Junction Box) 2.2. Customer drawings 2306314 (Flap), 2306315 (No Flap), 2307520 (Large Flap): S-Clip Termination Versions• Available in E-W and N-S rail directions to cover all possible module layouts • Provides waterproof protection and is rated IP68 (1 m / 24 hours) • Use of vent for humidity control • Includes integrated PV4-S interface into the junction box SOLARLOK PV EDGE DECENTRALIZED JUNCTION BOX ApplicationsSOLARLOK Z-Rail Junction Boxes 411-18305-1 SOLARLOK Interconnect System 411-137003 4 IN 1 tool for Z-rail Omega foil-clip installation 114-137077 PV4-S application specification . 114-13303-1 Rev.E1 3 of 18 3. REQUIREMENTS 3.1. Safety — Appropriate gloves and eye protection must be used throughout the entire installation of the junction box. .

SOLARLOK Z-Rail Junction Boxes 411-18305-1 SOLARLOK Interconnect System 411-137003 4 IN 1 tool for Z-rail Omega foil-clip installation 114-137077 PV4-S application specification . 114-13303-1 Rev.E1 3 of 18 3. REQUIREMENTS 3.1. Safety — Appropriate gloves and eye protection must be used throughout the entire installation of the junction box. . TE Connectivity’s SOLARLOK PV Edge Decentralized Junction Boxes are IP68 rated, providing waterproof protection at 1m for 24 hours. Features Quick installation time with a line and no potting necessary; . Available in E-W and N-S rail directions to cover all possible module layouts; Provides waterproof protection and is rated IP68 (1m/24 hours)TE News SOLARLOK 1-Rail Junction Box: Ideal for Thin-film Modules with Separate Access Points for Positive & Negativ. http://ow.ly/1d7Bmv

blue metallic fabric for sale

SOLARLOK Z-Rail Junction Boxes 411-18305-1 SOLARLOK Interconnect System 411-137003 4 IN 1 tool for Z-rail Omega foil-clip installation 114-137077 PV4-S application specification . 114-13303-1 Rev.E1 3 of 18 3. REQUIREMENTS 3.1. Safety — Appropriate gloves and eye protection must be used throughout the entire installation of the junction box. .

SOLARLOK Z-Rail Junction Boxes 411-18305-1 SOLARLOK Interconnect System 411-137003 4 IN 1 tool for Z-rail Omega foil-clip installation 114-137077 PV4-S application specification . 114-13303-1 Rev.E1 3 of 18 3. REQUIREMENTS 3.1. Safety — Appropriate gloves and eye protection must be used throughout the entire installation of the junction box. .

• Available in E-W and N-S rail directions to cover all possible module layouts • Provides waterproof protection and is rated IP68 (1 m / 24 hours) • Use of vent for humidity control • Includes integrated PV4-S interface into the junction box SOLARLOK PV EDGE DECENTRALIZED JUNCTION BOX Applications

1. SCOPE 1.1. Content This specification covers performance, tests and quality requirements for the Tyco Electronics SOLARLOK 1 Rail Junction Box used for distributing energy captured by solar panels used in the Photovoltaic (PV) industry. The one set consists of two type connection boxes, non- diode type and diode type.SOLARLOK Z-Rail Junction Boxes 411-18305-1 SOLARLOK Interconnect System 411-137003 4 IN 1 tool for Z-rail Omega foil-clip installation 114-137077 PV4-S application specification . 114-13303-1 Rev.E1 3 of 18 3. REQUIREMENTS 3.1. Safety — Appropriate gloves and eye protection must be used throughout the entire installation of the junction box. .SOLARLOK Z-Rail enhanced junction box for 1500V applications is manufactured with durable materials that reduce the stress on individual components, extend the life of the product and increase reliability.The junction box provides a flexible, open system structure,The SOLARLOK 1-rail junction box is 58mm x 30mm large, and 13mm high. It can be installed quickly and discreetly, and is also suitable for building-integrated PV systems. With this solution, module manufacturers can save not only two-thirds of the wiring, but can also offer customers better-looking panels.

SOLARLOK Z-Rail enhanced junction box for 1500V applications is manufactured with durable materials that reduce the stress on individual components, extend the life of the product and increase reliability.The junction box provides a flexible, open system structure,The junction box assembly must be protected from external forces that could cause it to be moved during curing. 3.2.8 Wiring the Junction Box 3.2.8.1 Foil Tab Connection The foil tab extended from the PV panel requires a soldering connection with the contact rail of Solarlok PV BAR Junction Box, the recommended foil tab width is 6mm Max.

SOLARLOK Z-Rail Junction Boxes 411-18305-1 SOLARLOK Interconnect System 411-137003 4 IN 1 tool for Z-rail Omega foil-clip installation 114-137077 PV4-S application specification . 114-13303-1 Rev.E1 3 of 18 3. REQUIREMENTS 3.1. Safety — Appropriate gloves and eye protection must be used throughout the entire installation of the junction box. .SOLARLOK Z-Rail enhanced junction box for 1500V applications is manufactured with durable materials that reduce the stress on individual components, extend the life of the product and increase reliability.The junction box provides a flexible, open system structure, TE provides two suitable junction boxes for crystalline modules: a clamped version and a soldered one. The SOLARLOK automated junction box will be unveiled at the Intersolar trade fair (June 8 to 10 in Munich, Germany) and will be available worldwide from July 2011. View additional information about the new SOLARLOK automated junction box.

The SOLARLOK 1-rail junction box is 58mm x 30mm large, and 13mm high. It can be installed quickly and discreetly, and is also suitable for building-integrated PV systems. With this solution, module manufacturers can save not only two-thirds of the wiring, but can also offer customers better-looking panels.SOLARLOK Z-Rail Junction Boxes 411-18305-1 SOLARLOK Interconnect System 411-137003 4 IN 1 tool for Z-rail Omega foil-clip installation 114-137077 PV4-S application specification . 114-13303-1 Rev.E1 3 of 18 3. REQUIREMENTS 3.1. Safety — Appropriate gloves and eye protection must be used throughout the entire installation of the junction box. .The SOLARLOK micro junction box terminates the foils of thin film, as well as Crystalline PV panels by soldered or welded connections while supporting voltage ratings of 1000V for UL3730 and 1000V for IEC62790. SOLARLOK micro junction box for 1000V applications is manufactured with durable materials that reduce the stress on individual components.The SOLARLOK 1-rail junction box is 58mm x 30mm large, and 13mm high. It can be installed quickly and discreetly, and is also suitable for building-integrated PV systems. With this solution, module manufacturers can save not only two-thirds of the wiring, but can also offer customers better-looking panels.

The junction box assembly must be protected from external forces that could cause it to be moved during curing. 3.2.8 Wiring the Junction Box 3.2.8.1 Foil Tab Connection The foil tab extended from the PV panel requires a soldering connection with the contact rail of Solarlok PV BAR Junction Box, the recommended foil tab width is 6mm Max.

SOLARLOK 1 Rail Junction Box System

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc .

solarlok 1-rail junction box|Class 1 Document