how do you calculate temp of electrical enclosures This heat sink size calculator will calculate the heat sink width and number fins . I'm interested in replacing an existing outlet (in a wall that's finished with drywall) with a two-gang duplex (four outlets total), using an "old work" box. This box is located in the garage, so I'd like it to be sturdy. Is it considered good .

0 · temperature rise in enclosure calculator

1 · sealed enclosure temperature rise calculator

2 · sealed enclosure temperature calculation

3 · heat rise in enclosure calculator

4 · enclosure temperature rise formula

5 · electronics enclosure temperature calculator

6 · electronic enclosure temperature rise

7 · battery enclosure temperature calculation

Handling heavy metal sheets is easier than ever before with the TAWI vacuum grippers. Maximum speed with minimal effort. Secure grip for efficient, reliable lifting. Tilt and rotate up to 180 degrees. Our most versatile vacuum lifter has the ability to lift goods of all shapes and sizes up to 600 lbs effortlessly and efficiently.

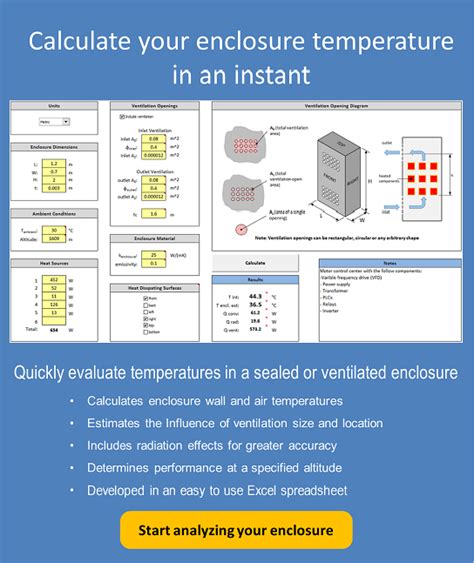

Accurately calculating the temperature rise of each component housed inside the enclosure is a complicated task that is best accomplished using computational fluid dynamics and heat transfer software.The enclosure temperature rise calculator is used to calculate the average internal .This heat sink size calculator will calculate the heat sink width and number fins . To use the calculator, enter the height, length, and width of the box first, then press the button "Calculate Surface Area." Then enter the wall thickness, material or thermal conductivity, and the air temperature.

Calculating an electrical enclosure's heat dissipation rate is the first step to prolonging the life of your electrical components. Use the following information to calculate input power and temperature rise and determine the heat dissipation .Use this enclosure heat calculator to estimate temperature rise inside of an enclosure given dimensions and power load.

Here’s a simplified set of steps for calculating an electrical enclosure’s temperature rise: First, find the input power, expressed in watts per square foot. Take the amount of heat dissipated within the enclosure in watts .First calculate the surface area of the enclosure and, from the expected heat load and the surface area, determine the heat input power in watts/ft. 2 Then the expected temperature rise can be .

temperature rise in enclosure calculator

The enclosure temperature rise calculator is used to calculate the average internal air temperature of a cuboid enclosure with internal heat generating components cooled via natural convection and radiation.heat dissipated in the enclosure (in watts) by the enclosure surface area (in square feet). Locate on the graph the appropriate input power on the horizontal axis and draw a line vertically until it intersects the temperature rise curve. .How to calculate the temperature in a ventilated electronics enclosure. Electrical and electronic components are sometimes housed in enclosures with ventilation openings to allow ambient air into the enclosure to more efficiently cool heat .

Hi! Check the full course on my website www.AppliedElectricalDesign.com where I also have a lot of other courses that cover EPLAN and Electrical Design of in.

Finding the perfect AC unit for your enclosure is vital to controlling maximum enclosure temperatures, keeping out harmful agents, extending equipment life, .Use this enclosure heat calculator to estimate temperature rise inside of an enclosure given dimensions and power load. . This includes electrical terminations, start/stop controls, HMI, relays, and other electrical components. .Example: Find the expected temperature rise from a 48″ x 36″ x 16″ electric enclosure with 300 watts of heat dissipated. Calculate Surface Area: 2 x ((48 x 36) + (48 x 16) + (36 x 16)) / 144 = 42 ft 2 Determine Input Power: 300 watts / 42 ft 2 = 7.1 watts/ft 2 Use the graph to find the Temperature Rise The thermal dissipation of an electrical enclosures is one of the most important elements to consider before installing the cabinet itself. For this reason, it’s necessary to calculate the thermal balance of the electrical cabinet in order to preserve the devices correct functioning and to make any necessary adjustments to ensure an optimal temperature inside. [.]

Fan Selection Example. A NEMA 12 Hubbell Wiegmann N12302412 enclosure (30″ high x 24″ wide x 12″ deep) contains a GS3-2020 AC drive (20 HP 230 volt) that has a maximum allowable operating temperature of 104°F and is located in a warehouse that has a maximum outside ambient air temperature of 95°F. Using the Calculator, the required wattage for the heater is found to be 16W. Applications of the Enclosure Heater Calculator . The Enclosure Heater Calculator finds its applications in various areas, predominantly in industries that require precise temperature control for their electrical and electronic equipment. These include but are not .The air flow through the enclosure is driven by the difference in air density of the cooler air outside the enclosure and warmer air inside due to the heat transferred from the heat generating components. As the air flows vertically through the lower ventilation openings and across the heat generating components its temperature increases.

Move a slider to your specified cooling requirement (Qc) and click the SEARCH button. As you move the slider to the right, multiple product categories may offer suitable standard solutions. You will see multiple sliders moving simultaneously at this time. The optimum thermal management solutions will display below the sliders.Wattage Calculator. The wattage of the heater you need is determined by the total surface area of your enclosure and the temperature rise you need to produce. You can use this calculator to find the wattage you need. (Note: This calculator has a maximum temperature rise of 140°F or 78°C)Step 1: Find your enclosure's total surface area by entering its dimensions here. Before we dig right into the math, keep in mind you can submit the following parameters to EXAIR and we will do the math for you. You can use our online Cabinet Cooler Sizing Guide and receive a recommendation within 24 hours.. There are two areas where we want to find the amount of heat that is being generated in the environment; this would be the .

The size of the air to air heat exchanger can be easily determined using an Enclosure Temperature Management Calculator. Ambient temperature above enclosure temperature: If the ambient temperature is higher than the enclosure design temperature, it’s necessary to use an enclosure air conditioner that can reduce the internal air temperature to .

How do you calculate heat dissipation in electrical enclosures? Qv – Heat loss installed in the enclosure (W) Qs – Thermal radiation via enclosure surface Qs = k *A * ∆T Qk – Required useful cooling output (W) ∆T – Temperature difference between inside and outside temperature (K) ∆T = (Ti-Tu) Qe – Required cooling output (W) Qe = Qv – Qs V – Required .

To do this, there must be a temperature differential between the ambient air and the enclosure air. The larger the temperature differential, the more effective the enclosure fan cooling will be. To get the most out of enclosure fans, determining ambient temperature extremes at the electrical cabinet location is important. Additionally the .In order to prevent unplanned downtime or equipment failure, you need to know the following facts about electrical enclosure temperature control. Search 972.580.0200 or 888.580.0202 $\begingroup$ You should be able to find the U value of the box material, in W/m²K, where K is the temperature difference across the box material. Given the U value, the surface area of the box, and the heat being .

If you do not know the power used in the enclosure but you can measure temperatures, then measure the temperature difference between the outside at current temperature, and the present internal cabinet temperature. Note the . So the temperature inside the box will depend on the watts of heat generated, the area of the box walls, the material of the box walls, and the outside temperature. This calculator can tell you the approximate temperature rise in the box, which you can apply. Note: this calculator deals only with conduction, not radiation.

sealed enclosure temperature rise calculator

Then you need to figure out what the desired operating temperature is for your enclosure. With these two numbers, you can figure out the temperature differential by subtracting the ambient temperature from the desired temperature. Determining Wattage Requirements for Enclosure Heaters. Why You Need to Get it Right. Many enclosures, especially .

How do you calculate the temperature rise of copper wire? For example a 2kg copper wire with 150W dissipated as heat electrical power on the wire, will rise above ambient temperature ΔΤ=50°C in 256 s. Thus ~4min. . How to calculate heat load in .but why do you need 60C? The thermal resistance is a constant and doesn't depend on the temperature. You need just few degrees higher than the ambient. If you heet with a X wats, and you get equliobrium Y degrees above the ambient, then you just devide X by Y and you will get how many wats per Kelvin is the thermal flow through the walls. $\begingroup$ The most difficult part is knowing the rate at which you lose heat to the surrounding air. But good thing you don't need to know since your temperature rise low, your volume is small, and time fairly long. I'd just get an element I know is vastly overpowered like a 500W or 1000W element and use feedback to turn the element off when the temperature is .

Considerations for Selecting an Electrical Enclosure Cooling Solution October 25, 2024 - 9:06 AM Crafting Proactive Thermal Management Plans for Electrical Enclosures September 3, 2024 - 8:52 AM 3D-Coverage Enhances Fire Safety with Performance-Based Standards for Emergency Signaling August 26, 2024 - 8:55 AM How do you calculate minimum box size when choosing electrical boxes? To calculate the minimum box size, you need to determine the total volume of all the wires, devices, and fittings that will be in the box. Each wire and device has a specific volume factor assigned in cubic inches. Add up these volume factors and choose a box that meets or .

Also, remember, the surface area affects the heat load of an electrical enclosure. That is, to calculate the electrical enclosure conductance, you must know the surface area (which is its size). Electrical Enclosure Conductance = Enclosure Surface Area ×Enclosure Heat Transfer Coefficient. How do You Calculate the Standard Enclosure Surface Area?The accepted approach is to take the temperature rise of the enclosure then subtract this from the permissible rise of the electrical device to calculate a derating. The aim is to control the maximum temperature so if the ambient is hotter, the temperature rise of the device must be lower. (See Graph 2). For many electrical products the current . Enclosure sizing and Heat Dissipation presented by Galco TV.This video shows the temperature rise in an enclosure and proper solutions to reduce the amount o.

coal truck steel ore box

sealed enclosure temperature calculation

Effectively you cut the wire on the ring feeding a new wire to socket via a juction box, then feed a wire from socket back to the other wire on the ring via a juntion box. Extending the ring gives you the option to extend in the future.

how do you calculate temp of electrical enclosures|battery enclosure temperature calculation