cnc machine vs cad CAD and CAM software, while different, work best in tandem. CAD provides the information-dense digital models that a CAM system needs to program manufacturing. CAM writes intuitive G-code that in turn makes CAD . $895.00

0 · software used in cnc machines

1 · programming software for cnc machines

2 · free cad software for cnc

3 · cnc milling machine programming software

4 · cnc machine software download

5 · cnc machine file types

6 · cad drawing for cnc machine

7 · best cabinet software for cnc

$34.99

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are distinct yet complementary technologies in the CNC machining process. CAD focuses on creating digital 3D models of parts or products, while CAM translates these designs into machine .The main difference between CAD/CAM and CNC lies in their focus. CAD/CAM .

At Rainhouse, we use cutting-edge CAD/CAM technology to ensure every project meets the highest standards of quality and precision. Contact us today to learn how we can help bring . CAD and CAM software, while different, work best in tandem. CAD provides the information-dense digital models that a CAM system needs to program manufacturing. CAM writes intuitive G-code that in turn makes CAD .CAD: Computer-Aided Design. This is where it all begins. Software like Fusion 360 and Mastercam empower users to craft intricate 3D designs. Essentially, you can create the digital version of a part, with specific dimensions and features . Key Takeaways. What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave .

The main difference between CAD/CAM and CNC lies in their focus. CAD/CAM software is primarily used for design and modeling, allowing engineers to create intricate and detailed 2D and 3D models.

Computer-aided Manufacturing (CAM) is commonly defined as the use of software to automate manufacturing processes. CAM software is able to translate CAD designs into instructions for machines, increasing the efficiency .

Here are a few of the pros and cons of the different approaches: Efficiency: CAM software automates much of the CNC programming process. It can often take only a few minutes to generate a complete CNC program. This .Computer Aided Design (CAD) is software that provides the ability to develop and design parts digitally. Essentially, you can create the digital version of a part, with specific dimensions and features (like chamfers, finishes, etc.) and use that . What is a Laser Cutter/Engraver? The laser cutter is a type of cutter that uses a super-focused beam of light to burn or melt away material for cutting or engraving. The laser machine is fed with a laser cut file, which has all the .

Choosing between 3-axis and 5-axis CNC machines. When it comes to accurate high-speed machining, both 3-axis and 5-axis CNC machines have great capabilities but with notable distinctions between them. 5-axis CNC . Home CNC Horizontal Machining Centers, . Feel free to run the machine manually by cranking the handles and using the control as a very advanced DRO (digital read-out). . Integration: Many CAM software .

Good day, I'm about to get my first CNC machine to enhance my offerings as a custom furniture maker. The Axiom I'm buying comes with V-Carve Pro -- which I'll use for CAM -- but I'm considering three options for the CAD side.

Subject - CAD/CAM/CAEVideo Name - Introduction to NC and CNC Machine ToolChapter - Design to Manufacturing Faculty - Prof. Sushant PatilUpskill and get Place. Read the manual: Before using a CNC machine, be sure to read the manual and understand the proper use of the machine. Get training: If you’re not familiar with how to use a CNC machine, be sure to get training from a qualified instructor. Use the proper tools: When using a CNC machine, be sure to use the proper tools and accessories.

Basics of CNC Machine Axes Linear Axes. The Cartesian Coordinate System is a reference system widely used in mathematics and other areas such as computer-aided design (CAD) and manufacturing. It is within the domain of manufacturing that CNC machines fall. This system is based on the concept of three mutually perpendicular axes that intersect at the origin.Explore the differences between CNC routers and CNC mills in terms of material compatibility, precision, speed, and cost. Learn why CNC routers are ideal for cutting softer materials like wood and plastics, while CNC mills excel in machining metals with higher accuracy and tight tolerances. Discover which machine is best suited for your project's size, complexity, and budget.

We have a new Tornos ST 26 and front side - backside - whoops both sides is requiring that we get ourselves some programming software.. anyone had any recent (last 2 years) experience with both Esprit and PartMaker with a Swiss style machine having two channels (front side and back side.For anything CNC related: CAD, CAM, automation, and more! Members Online • danyo41. ADMIN MOD FoxAlien 300w spindle vs 800w Rattmmotor . Working through the hurdles of learning on my first CNC machine - Foxalien Masuter 4040. Not the .

software used in cnc machines

CNC programming is a crucial aspect of modern manufacturing, enabling CNC machines to produce precise parts and components efficiently. By understanding the different types of CNC programming, manufacturers can choose the best approach for their specific needs and optimize their machining operations for success. The Maker Made M2 is the new and upgraded version of the original Maslow CNC. Modernized and upgraded for 2023, the Maker Made M2 still offers the fantastic 4 x 8 foot cutting range, as well as excellent 1mm accuracy, as well as a laser engraver upgrade kit.. For the extra money, you get an all-metal Z-axis, 40-inch cutting speed per minute, and built-in . Manual milling machines vs. CNC milling machines: a conclusion. As you already know, comparisons are only valid if you’re “comparing apples to apples,” as the saying goes. If that is so, it might be unfair to compare manual with CNC machines. After all, CNCs have so many advantages that they have turned manual milling machines into dinosaurs.Regardless if you manually create your G-code or use a CAM program, it’s a necessary component to making your CNC machine run. Every Piece of the CNC Puzzle. There are a million different ways to use CNC to create a part. You can change the type of machine you’re using or the CAD program or CAM or even a different post-processor and get .

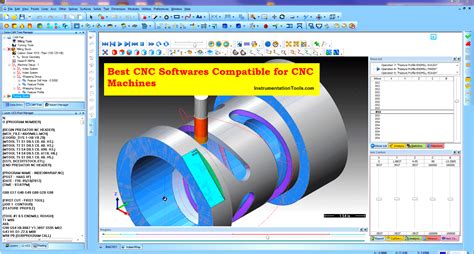

I have been thinking about an Elite Journeyman and I’m planning the space for it. Centimeters matter. I tried to find good drawings with precise dimensions, but it is proving difficult. Even if there were authoritative drawings, .CNC Machines (1458) CNC Mill (812) CNC Lathe (502) Vertical Machining Center (657) Horizontal Machining Center (142) Boring Mill (13) Router (104) EDM (21) Manual and Other Machining . Modeling: A digital model is created using . 2024 Best CAD/CAM Software for CNC Machines (Free & Paid) CNC programmers who are working with CNC machining, mechanical designing or manufacturing should be aware of the world-renowned CAD/CAM software. .How CAD Modeling Works with CNC Machines. CAD modeling is closely linked with CNC (Computer Numerical Control) machining. In a typical workflow, a designer creates a 3D model of a part using CAD software. This model is then translated into a series of instructions (G-code) that CNC machines use to precisely cut, shape, or form the part from raw .

With print in hand, the setup person can step up to the machine and quickly create the CNC program. Conversational controls allow programs to be entered without any need for math, and take much of the tediousness out of programming. . (CAD) system, which eliminates the need for the programmer to define the workpiece size and shape. The . Check out this handy guide to the different types of CNC machines from Scan2CAD. Scan2CAD. Blog. Convert files for CAD & CNC . CNC Machines Compared. Updated Jan 25, 2023. By Andy. Published Apr 18, 2017 in CNC. CAD software goes hand in hand with CNC machining, enabling users to create a wealth of both industrial and creative products. .The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! . cnc machine ×. Advertisement . CATIA V5, STEP / IGES, Rendering, August 17th, 2017 Deep Foundation Machine. by erhan topdemir. 0 2 0. AutoCAD, August 18th, 2017 NotMine. by Thomas Marquez. 0 4 0 .

sheet metal for carports

CAD vs. CAM. We already know that, in the CNC workflow, three steps are required to turn an idea into a finished product. First, obtain the model file. Second, transform the model file into commands that CNC machines can execute. Third, import the commands into a CNC machine to start carving till we obtain the finished product.Discover a comparison of the best CNC software (CAD, CAM, CNC control software), including free and open source options, and choose the best software for your CNC router according to your projects. . For more information on how best to generate G-Code from FreeCAD and use it on your CNC machine, see our dedicated tutorial. VCarve (CAD + CAM .Programming a CNC machine involves writing or generating G-code, which is the language that CNC machines understand. This code can be written manually or created using CAM (Computer-Aided Manufacturing) software, which translates CAD designs into machine instructions.

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! Learn about the GrabCAD Platform. Get to know GrabCAD as an open software platform for Additive Manufacturing . Cnc Router Machine. Show more. Download files Like. Share. 24 Downloads 6 Likes 0 . CNC Machine works with CAD/CAM software and G code for automated machining. The programming begins using CAD software to create a digital design. Then CAM translates the CAD-based design and generates the necessary parameters and instructions. For specific operations, CNC machines are equipped with different tools and accessories.Over the decades, CNC machines have undergone significant advancements, including the integration of CAD/CAM software, multi-axis machining, and the use of high-speed spindles. Today, CNC machines are essential in modern manufacturing, offering unparalleled precision and efficiency. The Role of CNC Machines in Various Industries Automotive Industry

sheet metal for fabrication

$699.60

cnc machine vs cad|cnc milling machine programming software