electrical enclosure thickness Here’s a quick breakdown: 6 x 6 inches: Used for small electrical panels and basic installations. 12 x 12 inches: Fits more components, perfect for home projects. 24 x 18 inches: .

To determine the drill bit size for a #14 screw, it’s based on the pilot hole size and whether it’s softwood or hardwood. For softwood, use a size drill bit of 5/32 inches, and for hardwood, use a size drill bit of 11/64 inches.

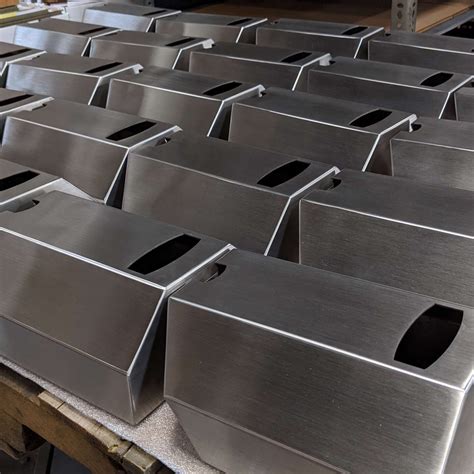

0 · sheet metal enclosures

1 · sheet metal enclosure thickness

2 · sheet metal enclosure design requirements

3 · sheet metal enclosure design guide

4 · metal enclosure thickness

5 · electronic enclosure design guide

6 · electronic enclosure design

7 · aluminum enclosure thickness

How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your convenience, the tables are reproduced here.

Engineers typically decide gauge or thickness on a case-by-case basis. The best place to start is taking inventory of your product needs and evaluating material type, weight and strength requirements and allowable flex. Next, discuss your .• JIC or Joint Industrial Commission ratings are standards which (in brief) specify minimum allowable material thickness for various enclosure sizes. In general, Hammond Enclosures . As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make .

An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical .Nema Enclosures designs and manufactures NEMA rated electrical enclosures in the following NEMA standards: NEMA 1. NEMA 3RX. Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel . Here’s a quick breakdown: 6 x 6 inches: Used for small electrical panels and basic installations. 12 x 12 inches: Fits more components, perfect for home projects. 24 x 18 inches: . These are the sheet metal thickness, material, size, and interior layout. For thickness, we use anywhere between 16 gauge and 3/16” depending on the strength .

Flange length must be a minimum of 4x material thickness. This is due to the need to maintain three points of contact with the form tooling — two points (one on either side of the bottom die and with a center point of the punch).The following dimensions are recommended for conventional Sheet metal enclosures: Height size series: 1600mm, 1800mm, 2000mm, 2200mm. Width size series: 400mm, 600mm, 800mm, 1000mm, 1200mm. Depth size series: .Engineers typically decide gauge or thickness on a case-by-case basis. The best place to start is taking inventory of your product needs and evaluating material type, weight and strength .• JIC or Joint Industrial Commission ratings are standards which (in brief) specify minimum allowable material thickness for various enclosure sizes. In general, Hammond Enclosures are. In Europe, IEC ratings are the most commonly recognized standards for enclosures.

The thickness often determines the strength, weight, flange length, and punch size of your enclosure. As you may know, it is usually difficult to make smaller products out of thicker metal. Furthermore, increasing material thickness is . As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make enclosures, including aluminum, stainless steel, carbon steel (cold-rolled steel or galvanneal) and copper.

An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical shock hazards and devices protected from hazardous environments as well as accidentalNema Enclosures designs and manufactures NEMA rated electrical enclosures in the following NEMA standards: NEMA 1. NEMA 3RX. Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts. Here’s a quick breakdown: 6 x 6 inches: Used for small electrical panels and basic installations. 12 x 12 inches: Fits more components, perfect for home projects. 24 x 18 inches: Ideal for larger setups like industrial machinery. 36 x 30 inches: Used for complex, heavy-duty systems with many components.

These are the sheet metal thickness, material, size, and interior layout. For thickness, we use anywhere between 16 gauge and 3/16” depending on the strength requirements and any applicable UL or NEC requirements. Flange length must be a minimum of 4x material thickness. This is due to the need to maintain three points of contact with the form tooling — two points (one on either side of the bottom die and with a center point of the punch).The following dimensions are recommended for conventional Sheet metal enclosures: Height size series: 1600mm, 1800mm, 2000mm, 2200mm. Width size series: 400mm, 600mm, 800mm, 1000mm, 1200mm. Depth size series: 600mm, 800mm, 1000mm, 1200mm.

Engineers typically decide gauge or thickness on a case-by-case basis. The best place to start is taking inventory of your product needs and evaluating material type, weight and strength .

• JIC or Joint Industrial Commission ratings are standards which (in brief) specify minimum allowable material thickness for various enclosure sizes. In general, Hammond Enclosures are. In Europe, IEC ratings are the most commonly recognized standards for enclosures. The thickness often determines the strength, weight, flange length, and punch size of your enclosure. As you may know, it is usually difficult to make smaller products out of thicker metal. Furthermore, increasing material thickness is .

As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make enclosures, including aluminum, stainless steel, carbon steel (cold-rolled steel or galvanneal) and copper.

An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical shock hazards and devices protected from hazardous environments as well as accidentalNema Enclosures designs and manufactures NEMA rated electrical enclosures in the following NEMA standards: NEMA 1. NEMA 3RX. Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts. Here’s a quick breakdown: 6 x 6 inches: Used for small electrical panels and basic installations. 12 x 12 inches: Fits more components, perfect for home projects. 24 x 18 inches: Ideal for larger setups like industrial machinery. 36 x 30 inches: Used for complex, heavy-duty systems with many components.

sovereign precision deluxe model 202 sewing machine belts and parts

These are the sheet metal thickness, material, size, and interior layout. For thickness, we use anywhere between 16 gauge and 3/16” depending on the strength requirements and any applicable UL or NEC requirements. Flange length must be a minimum of 4x material thickness. This is due to the need to maintain three points of contact with the form tooling — two points (one on either side of the bottom die and with a center point of the punch).

sheet metal enclosures

sheet metal enclosure thickness

We find multiple types of junction boxes with their properties and advantages. For this reason, we categorize these electrical junction box types based on their features and applications. We will discuss each type in the following section to help you spot the best type for your requirements.

electrical enclosure thickness|sheet metal enclosure design requirements