how many axis can a cnc machine have Fundamentally, CNC machines operate along three core linear axes: X, Y, and Z. These refer to back-and-forth (X), left-and-right (Y), and up-and-down (Z) motions on flat planes. Extra rotating axes labeled A, B, and C . Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. It involves removing excess material from a workpiece, bringing it to its desired size and shape.

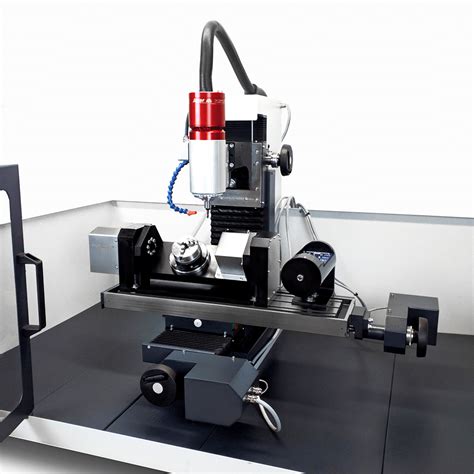

0 · 5 axis milling machines

1 · 5 axis cnc router

2 · 5 axis cnc mill router

3 · 5 axis cnc mill

4 · 4 axis cnc router milling

5 · 4 axis cnc milling

6 · 3 axis cnc milling machines

7 · 3 axis cnc machine

I sold my BP to get my tree 2uvr I cant stand draw bars. The tree is a far better mill than a BP the BP won out because it was cheap compared to the Tree. BP made thousands of those mills they are the least expensive toolroom mill made kinda of like the Haas of manual mills. I believe the tree cost more than double what a BP cost when new.

A 4-axis CNC machine functions much like its 3-axis counterpart. The workpiece is in a stationary position, and the cutting tool works on it to remove material and mold the desired part. .

3 Axis CNC Machine. A 3-axis machine is capable of moving independently in three directions, not including the rotation of the spindle itself. Every axis of travel means an additional degree of freedom for the machine’s . Fundamentally, CNC machines operate along three core linear axes: X, Y, and Z. These refer to back-and-forth (X), left-and-right (Y), and up-and-down (Z) motions on flat planes. Extra rotating axes labeled A, B, and C .

To achieve ultimate precision in CNC machining, linear and rotary axes play a crucial role. Linear axes provide linear movement in addition to the primary X, Y, and Z axes, enabling versatility .

If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. 4-axis: Includes a .Common configurations include 3-axis, 4-axis, 5-axis, and even more advanced options. The number of axes determines the machine's ability to move in multiple directions simultaneously and perform complex operations with enhanced . A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move .

The Three Common Axis Configurations (250 words) 1. 3-Axis CNC Machines: Definition and Functionality. Applications and Limitations. 2. 4-Axis CNC Machines: Introduction to the .While a three-axis CNC machine is highly versatile, there are instances where additional axes are required to implement more complex operations. Let's explore some of the advanced axis configurations found in modern CNC machines: 1. Four-Axis CNC Machines (XYZA):\ A four-axis CNC machine adds an A-axis to the traditional three-axis system.IV. Specialized CNC Axis Configurations (200 words)\ Apart from the common 3, 4, and 5-axis CNC machines, there are several specialized configurations available. This section will provide an overview of some notable variations, such as: 6-Axis CNC Machines . Multi-Tasking CNC Machines . Swivel Head CNC Machines

Generally, CNC machines have three axes: the X-axis, Y-axis, and Z-axis. The X-axis is the horizontal movement, the Y-axis is the vertical movement, and the Z-axis is the depth movement. Some CNC machines may .Overall, the 3 axis machine would take 5 hours and 15 minutes to manufacture a single component. 5 axis CNC – operations described. It’s all so much easier with a 5 axis machine! Just two operations as follows: combines 3 axis operations 1 – 3 and 5 – 7: Partial profiling to allow handling of excess stock. Set in vice, set datum.By understanding how many axes a CNC machine can have and their functionalities, manufacturers can make informed decisions to achieve the desired results. Understanding Axis in CNC Machines. . Their CNC machines can be equipped with 3-axis, 4-axis, or even 5-axis configurations, providing flexibility for different applications. . With many of the same customizations available as on 3-axis machines these can be fitted to handle many materials and applications. 5-Axis CNC Routers. 5-axis routers operate along the same X-, Y-, and Z-axis as 3-axis routers but add two axes. As with 4-axis machines, they can rotate around the X-axis with the A-axis.

How Many Axis in CNC Lathe Machine? A CNC lathe machine typically has two primary axes: the X-axis, which runs horizontally, and the Z-axis, which runs vertically. However, some machines may also have a third axis, the Y-axis, which runs perpendicular to both the X and Z axes, allowing for more complex cuts and shapes.A 2-axis CNC controller allows machine tools to move in only two axes, X and Y. The cutting tools in these machines won’t go into Z axes. Examples of such machines are lathes and laser cutters. . Keep in mind that some CNC machines can also have six directional movements. The CNC axis controller is used in all of these types.

5 axis milling machines

CNC machines are an essential part of modern manufacturing, and they come in various shapes and sizes. When it comes to the number of axes, there are several But, in the world of CNC machines it seems the count only applies to how many axes can have simultaneous coordinated motion. Like a conventional milling machine with X,Y,Z and a rotary axis that only indexes is still considered 3 axis. Make that rotary axis capable of coordinated motion with the other axes and it's a 4 axis machine. The number of axes that a CNC lathe can have is an important factor in determining its level of precision and the complexity of the shapes it can create. In this article, we will explore the different types of CNC lathe axes and their functions.As evident from the name itself, a 5-axis CNC machine can be automatically manipulated from five axis at a single time. In addition to movements along the X, Y and Z axes, this type of machine can also choose two of the three rotational axes. The three rotational axes are also denoted by A-axis, B-axis, and C-axis.

laser sheet metal cutting exporter

A CNC machine can have up to six axes, with each axis controlling the movement of a specific part of the machine. The axes are represented using letters such as X, Y, and Z. The X-axis represents the horizontal movement of the machine, the Y-axis represents the vertical movement, and the Z-axis represents depth or the distance from the cutting .Series: Anatomy of a CNC: How many axes can a CNC have?

You would mostly just use the machine in 2D with the mill moving in and out of the panel to cut in a binary fashion. 2.5D software is likely cheaper and simpler to use. I think a 2.5D CNC hardware would be one with very limited Z axis travel and limited rigidity in the Z dimension. I don't think it means how many axis can be used at the same time.

lasermet distribution box

5 axis cnc router

CNC equipment has evolved rapidly in the past decade and it now provides more power and versatility than ever before. While most CNC machines operate along 3, 5 or 7 axes, multi-head machines can offer up to 12 axes of .Each of the 5-axis machine styles is suited to a specific type of work. We discuss the vertical 5-axis vs horizontal 5-axis debate. Contact; Support +44 (0) 23 9258 0371. . There are many different types of 5-axis CNC milling machines on the . Additionally, some machines may feature a V-axis, which provides additional movement perpendicular to the X, Y, and Z axes. The V-axis enables the CNC lathe to perform more intricate and multidirectional machining operations. Conclusion. In conclusion, the number of axes that a CNC lathe can have varies depending on the machine''s design and .

Lathes with three or more axes are commonly referred to as multi-axis CNC lathes. These machines offer increased flexibility and efficiency in machining complex parts with tight tolerances. 5-axis CNC lathes: A 5-axis CNC lathe incorporates five primary axes - X, Y, Z, C, and B. This configuration allows for simultaneous movement in all five .

Typical CNC machines have 2 or 3-axis movement (spindle or tool movement). Meanwhile, any machine beyond the 3-axis is known as the multi-axis machine. Typically, 4 and 5-axis CNC machines are popular in the manufacturing industry. However, they also come with 5, 3+2, 6, 7, 9, and 12 axes configurations. 4-axis CNC machines ; Expanding on the 3-axis foundation, 4-axis CNC machines introduce an additional rotating axis. Typically oriented vertically (designated the A or C axis), this fourth axis enables the workpiece to pivot and spin. The cutting tool can then approach from different angles without manual resets, making it easier to manufacture . 5 axis CNC machines can cut along two additional axis than 3 axis CNC machines. These routers have the ability to cut on five sides of a piece of material simultaneously, which expands the operator’s capabilities and flexibility. Unlike their 3 axis counterparts, these machines are usually used to cut large 3D parts.

Mach 3 CNC software can do the following: Converts a standard PC to a fully featured, 6-axis CNC controller Allows direct import of DXF, . CAD/CAM will get you as far as designing your parts and producing the g-code, but if you also want to run the CNC machine with your Mac, you will need a piece of software similar to Mach3 or EMC to run the .

The sound of chips hitting the machine has people flocking to the Ibarmia stand at AMB 2024!! Whether it’s the T series or the Z series, Ibarmia’s Gen2 models have so many different options you wouldn’t normally see at any exhibition. From standard milling and turning all the way to skiving, eccentric turning, elliptic turning, [.] The term “axis” in the context of CNC machines refers to the number of directions in which the cutting tool or workpiece can move relative to the machine’s frame. Each axis represents a degree of freedom, enabling intricate movements that are essential for machining complex geometries with precision. The axis configuration of a CNC .

If your part requires it then there is no much way around it. However, most parts don't, they're usually 3+2. My personal opinion is that for the cost of a 5 axis machine I can buy 2 3 axis machines and maybe get a 4th axis for 1 of them. And with this set up I don't think a 5 axis can produce as much.By the end of this guide, you will have a clear understanding of the role each axis plays in CNC machining, empowering you to fully comprehend and utilize these powerful machines to their fullest potential. 1. The X-Axis: The Backbone of CNC Machining\ The X-axis is arguably the most crucial component of any CNC machine.

5 axis cnc mill router

Triplus Co., Ltd., specializing in the production of auto body parts and production of automotive stamping tooling, injection tooling of classic valuable cars and trucks market for 20 years, and authorized to manufacture the General Motor (GM) Co. and the Chrysler Group (MOPAR) LLC licensed products

how many axis can a cnc machine have|4 axis cnc milling