cupping test for sheet metal The cupping test is performed to determine a metal's ability to deform under stretching forces. It is widely used in the metal manufacturing and paint industries and can be performed on sheets with thicknesses. Learn how to prevent warping in thin metal during welding. This informative article explores techniques, tips, and tricks for flawless, distortion-free results.

0 · olsen cupping test

1 · erichsen cupping test sheets

2 · cupping to erichsen standard

3 · cupping test to erichsen

4 · cupping machine for metal

Stamping Process in Sheet Metal. The stamping process in sheet metal involves several key steps to transform flat sheets into shaped components. It begins with designing the part and creating custom tooling, including dies tailored for precision and repeatability.

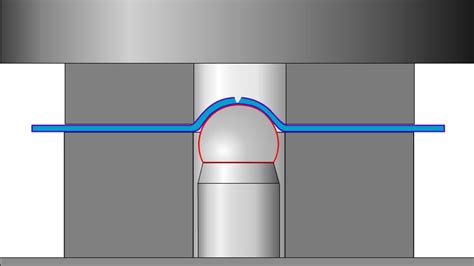

Erichsen cupping test for sheet metal is used for qualitative comparison of compositions, strength and physical properties amond metal sheets.The cupping test is a test method applied in the metalworking industry and is used to determine the ductility of sheet metals and strips. For the performance of cupping tests on sheet metal a spherical drawing punch is pressed into a .The ISO 20482 standard describes the cupping test to Erichsen and is used to determine the ductility of metal sheets and strips. The test is also standardized in ASTM E643 as cupping test to Olsen. An additional description can be found . The maximum depth \(f\) to which the steel ball is pressed, without cracking the sheet metal, is used to assess the deep-drawing capability. The cupping test can be used to test sheets up to 3 mm thick.

The cupping test is performed to determine a metal's ability to deform under stretching forces. It is widely used in the metal manufacturing and paint industries and can be performed on sheets with thicknesses. Modified Erichsen cupping test is on of the currently used formability test, which evaluate the ability of sheet metal to be formed into useful components successfully.

Typical sheet metal forming test methods include the classical cupping test to Erichsen (ISO 20482) and Olsen (ISO 20482), the earing test (ISO 11531 / EN 1669) and hole-expansion tests to ISO 16630, which are seeing increasing .For almost 100 years a test method to determine the level of quality of sheet metal exists. Abraham M. Erickson is considered the inventor of the cupping test and he patented this test method in the early 20th Century.

utility cabinet enclosure steel contour new made in usa

ISO 20482:2013 specifies a standard test method for determining the ability of metallic sheets and strips having a thickness from 0,1 mm up to 2 mm and a width of 90 mm or greater to undergo .The Erichsen deep-drawing test is used to determine the stretch-forming capacity of sheet metals in accordance with (DIN EN 10139 and DIN EN 10130), which have a thickness of 0.1 mm to 2 mm and a width of 90 mm or more. Erichsen cupping test for sheet metal is used for qualitative comparison of compositions, strength and physical properties amond metal sheets.The cupping test is a test method applied in the metalworking industry and is used to determine the ductility of sheet metals and strips. For the performance of cupping tests on sheet metal a spherical drawing punch is pressed into a clamped metal sheet until a crack appears.

The ISO 20482 standard describes the cupping test to Erichsen and is used to determine the ductility of metal sheets and strips. The test is also standardized in ASTM E643 as cupping test to Olsen. An additional description can be found in the Japanese standard JIS Z-224. The maximum depth \(f\) to which the steel ball is pressed, without cracking the sheet metal, is used to assess the deep-drawing capability. The cupping test can be used to test sheets up to 3 mm thick.The cupping test is performed to determine a metal's ability to deform under stretching forces. It is widely used in the metal manufacturing and paint industries and can be performed on sheets with thicknesses. Modified Erichsen cupping test is on of the currently used formability test, which evaluate the ability of sheet metal to be formed into useful components successfully.

Typical sheet metal forming test methods include the classical cupping test to Erichsen (ISO 20482) and Olsen (ISO 20482), the earing test (ISO 11531 / EN 1669) and hole-expansion tests to ISO 16630, which are seeing increasing use with high strength steel materials.

For almost 100 years a test method to determine the level of quality of sheet metal exists. Abraham M. Erickson is considered the inventor of the cupping test and he patented this test method in the early 20th Century.

ISO 20482:2013 specifies a standard test method for determining the ability of metallic sheets and strips having a thickness from 0,1 mm up to 2 mm and a width of 90 mm or greater to undergo plastic deformation in stretch forming.The Erichsen deep-drawing test is used to determine the stretch-forming capacity of sheet metals in accordance with (DIN EN 10139 and DIN EN 10130), which have a thickness of 0.1 mm to 2 mm and a width of 90 mm or more. Erichsen cupping test for sheet metal is used for qualitative comparison of compositions, strength and physical properties amond metal sheets.The cupping test is a test method applied in the metalworking industry and is used to determine the ductility of sheet metals and strips. For the performance of cupping tests on sheet metal a spherical drawing punch is pressed into a clamped metal sheet until a crack appears.

The ISO 20482 standard describes the cupping test to Erichsen and is used to determine the ductility of metal sheets and strips. The test is also standardized in ASTM E643 as cupping test to Olsen. An additional description can be found in the Japanese standard JIS Z-224.

The maximum depth \(f\) to which the steel ball is pressed, without cracking the sheet metal, is used to assess the deep-drawing capability. The cupping test can be used to test sheets up to 3 mm thick.The cupping test is performed to determine a metal's ability to deform under stretching forces. It is widely used in the metal manufacturing and paint industries and can be performed on sheets with thicknesses. Modified Erichsen cupping test is on of the currently used formability test, which evaluate the ability of sheet metal to be formed into useful components successfully.

Typical sheet metal forming test methods include the classical cupping test to Erichsen (ISO 20482) and Olsen (ISO 20482), the earing test (ISO 11531 / EN 1669) and hole-expansion tests to ISO 16630, which are seeing increasing use with high strength steel materials.

For almost 100 years a test method to determine the level of quality of sheet metal exists. Abraham M. Erickson is considered the inventor of the cupping test and he patented this test method in the early 20th Century.

olsen cupping test

Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in.

cupping test for sheet metal|olsen cupping test