cnc machine drive mechanism CNC machine tools are important and indispensable equipment in modern manufacturing. They rely on efficient and precise transmission systems and drive structures to .

Code Change Summary: Revised code section on box access. The previous language in 314.29 has been revised and formatted into a list for usability. The 2020 requirements still maintain that boxes and conduit bodies must be .

0 · what is a cnc motor

1 · what is a cnc machine pdf

2 · what is a cnc machine

3 · how does a cnc work

4 · how cnc machine works pdf

5 · function of cnc machine

6 · drive system of a cnc machine

7 · cnc machine parts pdf

CNC Resources & Education Explore our financing options and make your purchase more affordable. Learn more about how we can help you bring your projects to life.

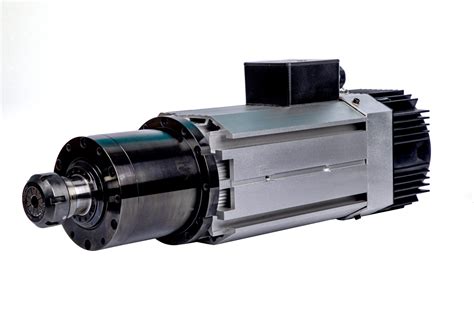

The drive components are the mechanical components that "drive" the CNC machine along its axis. The most common components associated with a drive system, are the motors, lead or ball screw, or rack and pinions. The drive system consists of motors responsible for moving the tool along the various axes of the CNC machine. In a standard CNC mill, the bed .To understand the functioning of a CNC machine drive system, it is essential to grasp the concept of stepper motors and servo motors. We will delve into the fundamental differences between .There are several types of drives used in CNC machine tools, including servo drives, stepper drives, hydraulic drives, and pneumatic drives. Servo drives are commonly used due to their .

In CNC machines, this means the motor’s force is directly applied to the part being moved or machined, without belts, gears, or pulleys in between. Direct Drive technology ensures that the force from the motor is transmitted without . CNC machine tools are important and indispensable equipment in modern manufacturing. They rely on efficient and precise transmission systems and drive structures to .In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 1. Machine Control Unit (MCU) The Machine Control Unit is the brain .K+

5K+K+K+ Compare rack and pinion, belt drive, and ballscrew systems for CNC machining. Learn about the pros and cons of each option for your application. Explore now!

what is a cnc motor

The driving system of a CNC machine includes an amplifier circuit, drive motors, and ball lead screws. The MCU supplies the signals (ie, of position and speed) of each axis to the amplifier circuits. The control signals are then augmented (increased) to actuate the drive motors.

The drive components are the mechanical components that "drive" the CNC machine along its axis. The most common components associated with a drive system, are the motors, lead or ball screw, or rack and pinions.The drive system consists of motors responsible for moving the tool along the various axes of the CNC machine. In a standard CNC mill, the bed is horizontally moved along the x- and y-axes, while the cutting tool moves vertically along the z-axis.

To understand the functioning of a CNC machine drive system, it is essential to grasp the concept of stepper motors and servo motors. We will delve into the fundamental differences between these two types of motors and examine how each type enhances the performance of a CNC machine. – Drive Motors: Drive motors are responsible for moving the various components of the CNC machine. They receive signals from the CCU and convert them into mechanical motion. Common types of drive motors include stepper motors and servo motors.There are several types of drives used in CNC machine tools, including servo drives, stepper drives, hydraulic drives, and pneumatic drives. Servo drives are commonly used due to their high precision and ability to control position, velocity, and torque.In CNC machines, this means the motor’s force is directly applied to the part being moved or machined, without belts, gears, or pulleys in between. Direct Drive technology ensures that the force from the motor is transmitted without any loss.

what is a cnc machine pdf

CNC machine tools are important and indispensable equipment in modern manufacturing. They rely on efficient and precise transmission systems and drive structures to realize complex machining tasks.

In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. It reads the G-code (the programming language for CNC) and converts it into electrical signals that control the machine's movements. Compare rack and pinion, belt drive, and ballscrew systems for CNC machining. Learn about the pros and cons of each option for your application. Explore now!

hand sheet metal bender

The driving system of a CNC machine includes an amplifier circuit, drive motors, and ball lead screws. The MCU supplies the signals (ie, of position and speed) of each axis to the amplifier circuits. The control signals are then augmented (increased) to actuate the drive motors.The drive components are the mechanical components that "drive" the CNC machine along its axis. The most common components associated with a drive system, are the motors, lead or ball screw, or rack and pinions.

The drive system consists of motors responsible for moving the tool along the various axes of the CNC machine. In a standard CNC mill, the bed is horizontally moved along the x- and y-axes, while the cutting tool moves vertically along the z-axis.To understand the functioning of a CNC machine drive system, it is essential to grasp the concept of stepper motors and servo motors. We will delve into the fundamental differences between these two types of motors and examine how each type enhances the performance of a CNC machine. – Drive Motors: Drive motors are responsible for moving the various components of the CNC machine. They receive signals from the CCU and convert them into mechanical motion. Common types of drive motors include stepper motors and servo motors.

There are several types of drives used in CNC machine tools, including servo drives, stepper drives, hydraulic drives, and pneumatic drives. Servo drives are commonly used due to their high precision and ability to control position, velocity, and torque.In CNC machines, this means the motor’s force is directly applied to the part being moved or machined, without belts, gears, or pulleys in between. Direct Drive technology ensures that the force from the motor is transmitted without any loss. CNC machine tools are important and indispensable equipment in modern manufacturing. They rely on efficient and precise transmission systems and drive structures to realize complex machining tasks.

what is a cnc machine

In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. It reads the G-code (the programming language for CNC) and converts it into electrical signals that control the machine's movements.

how does a cnc work

how cnc machine works pdf

function of cnc machine

If a regular contribution is made to the HSA that is closed, and a distribution is made to the participant, enter the gross distribution in box 1. If no earnings are distributed, enter zero in .

cnc machine drive mechanism|how cnc machine works pdf