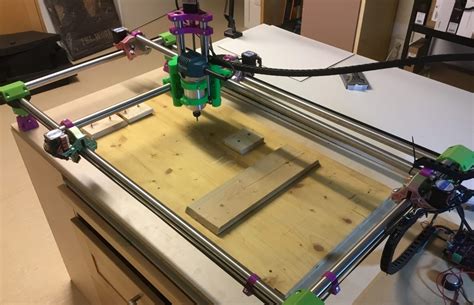

cnc router build part CNC Router Build Parts. We didn’t want the motors to be sticking out of the machine. Because this would increase the overall size of the machine by about 15 cm on each axis. Typically you would mount the motors on the outside of the . Weiss Sheet Metal, Inc. offers a wide range of stainless steel items and services for residential, commercial, and architectural projects. See their gallery of work for kitchens, food service, laboratories, and more.

0 · make your own cnc machine

1 · homemade cnc router plans

2 · homemade cnc router machine

3 · cnc homemade router

4 · building your own cnc

5 · build your own cnc router

6 · build your own cnc kit

7 · best cnc router for beginners

A 20-gauge sheet of steel would be 1/20 of an inch thick, and so on. Sheet steel weight for a particular gauge number would simply reflect the standardized density of steel and the standardized thickness of that gauge number.

make your own cnc machine

Bring your boldest ideas to life with CNC routers that deliver precision, durability, and ease of use. Whether you’re a hobbyist or a professional, our machines are built to help you turn . A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.CNC Router Build Parts. We didn’t want the motors to be sticking out of the machine. Because this would increase the overall size of the machine by about 15 cm on each axis. Typically you would mount the motors on the outside of the .

This kit includes parts and a detailed set of plans to build a CNC router. The components have been carefully selected to optimize performance and reliability. . The three main topics covered are CNC router design, building a CNC .

Part 3 of CNC router assembly.I now have a donate button on my HOME PAGE - Click herehttps://www.youtube.com/user/MyRobertadamsDonations are very .

Livestreams Every Weekday at 1:00 pm Eastern Join me and likeminded others on a livestream I host every weekday where I experiment, learn and discover. Topic for Tuesdays and Thursdays: CNC Discussion and Random Experiments. Topic for Mondays, Wednesdays and Fridays: Microcontroller programming and circuit building. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood. Discuss Build Build Author sharmstr Views 16341. 22 Likes 3 Tags 0 Reviews. Workbee 1510 Shawn's Workbee 1510. Jan 21, 2019. Category .All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood. Discuss Build Build Author sharmstr Views 16354. 22 Likes 3 Tags 0 Reviews. Workbee 1510 Shawn's Workbee 1510. Jan 21, 2019. Category .

Part 7 of CNC router assembly. Building the electronics panel.I now have a donate button on my HOME PAGE - Click herehttps://www.youtube.com/user/MyRobertad.

This video shows the assembly process of the DIY CNC router Lowrider V4. A quick introduction the CNC router project I have started. When finished, I'll be using it to cut precise parts for a number of future planned projects. The.

I decided I want to build a cnc mill for a project as well as having a good tool and hobby at the end. im starting to model what I want. ive got a good idea of what I want, im now starting to look for parts I can begin to model around. I plan on contacting a local steel supplier and ordering pre-cut steel plates for the body, and having those .With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router. . This OpenBuilds Mini Mill is a great go-to desktop sized CNC milling plate / part maker and 3D carving machine! . Build it - Share it! Collaborate on our forums and be sure to visit the Part Store for all your Maker needs.Part 2 of CNC router assembly. Building a table top cnc router using extruded aluminium with only basic tools at hand. Waiting on parts from China to complete the rest of the machine so pa.

CNC Router Parts, Mechanical for DIY CNC machines. Ball Screws, Linear Rails Guides, Motor Brackets, Couplings, Bearings. We are an online store from Canada. I can easily make single pass cuts in 3/4" material at very reasonable speeds and accuracy for a plywood hobby cnc machine. Twice so far, I've miss-judged locations of stock hold down screws and managed to mill .

homemade cnc router plans

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts. . With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router. Discuss Build . This OpenBuilds Mini Mill is a great go-to desktop sized CNC milling plate / part maker and 3D carving machine! Part 6 of CNC router assemblyI now have a donate button on my HOME PAGE - Click herehttps://www.youtube.com/user/MyRobertadamsDonations are very . Part 4 of CNC router assemblyI now have a donate button on my HOME PAGE - Click herehttps://www.youtube.com/user/MyRobertadamsDonations are very .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

Build a CNC Router From Scratch (Part 2): Complete Video Tutorial: If you haven't seen part 1, your CNC may look like a three legged dog. This is a multi-part instructable that demonstrates how to build a CNC Router (a computer controlled router) from scratch.CNC Machines can come in many shapes and sizes. Just l.

Part 9 of CNC router assembly. The completion! It's finally done! It's been a long haul, but well worth it. Looking forward to making pickup winder parts. Last installment of the CNC router build.Anyone interested in just the rubber band rifle.. starts at 26:00.ThisOldRouter CAD: https://drive.google.com/file/d.Build your custom Onefinity CNC router machine. This walkthrough takes you through each step of the ordering process making it an easy and complete way to get the CNC router machine you want. . Be Part of Our Community. Join our vibrant community of builders. Share your passion, expertise, and creativity - and learn how Onefinity’s CNC .If you are modifying your existing desktop mill to a desktop cnc machine, or you are building a DIY CNC router or DIY CNC machine of any type (including robots), our board is the best way to get the motors turning! . The boards are clearly labeled and the parts count is kept to a minimum to make assembly as easy as possible!

Part 5 of CNC router assemblyI now have a donate button on my HOME PAGE - Click herehttps://www.youtube.com/user/MyRobertadamsDonations are very much appreci.This video is part 1 in a 4 part series on building a new CNC Router. This video covers the design and components that I have decided on using.Link to the pl.

Part 8 of CNC router assembly. Testing the stepper motors and mounting them on the machine.I now have a donate button on my HOME PAGE - Click herehttps://ww.

Multifunctional high-performance machining center for turning operations or turn-mill complete machining in one or two setups. MULTIFUNCTIONAL VERTICAL TURNING CENTER. HORIZONTAL SHAFT TURNING CENTER. Unique, horizontal pick-up finishing machine and centering machine for shafts up to 650 mm in length - including overturning, milling, deep drilling.

cnc router build part|cnc homemade router