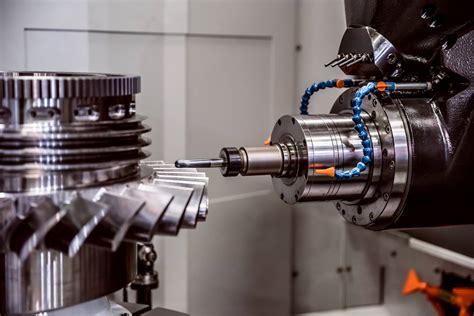

mass production cnc machining part Trace-A-Matic produces precision parts designed for high volume CNC machining while ensuring product quality. We have eight state-of-the-art facilities with 180+ machining centers, providing machining capacity tailored to the mass .

In this blog, we will compare BMT and VDI turrets to help you understand their differences and determine which one is the best fit for your manufacturing needs. What Is The BMT Turret? The BMT turret is a type of .

0 · The Art of Precision Metal Parts Production with CNC Machines

1 · Production CNC Machining: Everything You Need to

2 · Mass Production

3 · How to Mass Produce a Product: A Comprehensive Guide to

4 · How to Mass

5 · High Volume Machining

Whether you’re storing a heavy load, a light load, or need brackets for specific shelves, such as glass, corner or floating shelves – we have an extensive selection of brackets and fixings at B&Q. In this guide, we’ll talk you through .

Successfully mass-producing a product requires careful planning, robust systems, and continuous optimization. Key success factors include: Thorough product development and testing. . Mass production of custom parts, especially through CNC Machining, requires detailed planning and precision to meet exact customer requirements. At Formal, we .Mass production in CNC machining involves a high-volume manufacturing process with repetitive tasks to produce a large number of identical parts efficiently. Here are the key steps: 1. .

"Discover how CNC machining is revolutionizing metal part production. From 3D CAD designs to flawless metal components, this video covers the essential techn. Production CNC machining process involves leveraging CNC technology to attain high-scale production of different metal and non-metal parts and components with tight tolerances, superior quality, higher dimensional .Trace-A-Matic produces precision parts designed for high volume CNC machining while ensuring product quality. We have eight state-of-the-art facilities with 180+ machining centers, providing machining capacity tailored to the mass .A.W. Miller has been a leading distributor of precision machining equipment and tooling for the mass production industry in the USA and Canada since 1971. CNC turning centers, horizontal/vertical machining centers, and grinding machines are all available from our locations.

In this video, you can see our operators are working at the machine shop. Mass production of mechanical parts completed with computer controlled machining ce.

The Art of Precision Metal Parts Production with CNC Machines

The Transformation of CNC Machining: From Mass Production to Small Batches. CNC machining emerged in the era of mass production and has a considerable history. With the advancement of technology and the increase in manufacturing complexities, there has been a remarkable shift towards smaller and more customized batches.SH Auto Parts specializes in high-precision CNC machining for automotive components. With state-of-the-art machinery, we provide reliable, custom-made parts to meet the exacting standards of the global auto industry. . Precision robotic control for simultaneous mass production of different suspension components. . Perfect alignment of parts . CNC Mass provides expert CNC machining services for clients worldwide. Our team of skilled machinists uses state-of-the-art equipment and software to create precise parts according to your exact specifications. Whether you need a single prototype or a large production run, we can deliver the parts you need on time and within budget.2. The CNC Machining Process for Mass Production. CNC machining for mass production follows a systematic process that maximizes efficiency and productivity. Here are the key steps involved: Design and Programming: Skilled engineers and designers use computer-aided design (CAD) software to create a digital model of the component. The CAD model .

This ensures the parts can be machined as a whole in mass production to improve production efficiency. Conclusion. Splitting parts in CNC machining helps overcome limitations related to machine travel, material thickness, tool length, and part structure. It helps to broaden the usage of CNC machining and reduce costs. Therefore, these splitting .

Production CNC Machining: Everything You Need to

In CNC mass production, efficiency meets precision at every turn. However, while the results are consistently high-quality, initiating such large-scale machining endeavors often comes with a heftier price tag. It’s the trade-off between unparalleled quality and initial investment.Central Mass. Machine, Inc. is an ISO9001-2000 machine shop that specializes in the precision machining of large parts for the defense, power generation, aircraft, nuclear, photovoltaic, medical device, and commercial machinery industries. Central Mass. lifts up to 30,000 lbs., and has CNC full 5-axis milling, VTL's, Lathes, and Planers in very .

China Mass Production Cnc Parts wholesale - Select 2024 high quality Mass Production Cnc Parts products in best price from certified Chinese CNC Cutting Machine manufacturers, Cnc Machining Part suppliers, wholesalers and factory on Made-in-China.com . High Precision Mass Production CNC Machining Parts CNC Aluminum Milling Parts. US$ 2600 .

Mass Production Cnc Machining Part. Machine Type: CNC (Computer Numerical Control) Milling Machine Max Workpiece Size: 1000mm x 800mm x 500mm Tool Magazine Capacity: 20 Tools Spindle Speed: 10,000 RPM Control System: CNC System with Advanced Graphical User Interface Accuracy: ±0.01mm In mass production of parts, the most important are combined knowledge and experience of operators and precision of CNC machining services. Such resources can provide additional profits for the client – for example better selection of material for ordered jobs (cheaper alloy but with almost identical features) that can lead to cost optimization.

Advantages of CNC processing: 1. CNC automatic processing CNC machining usually refers to precision machining controlled by computer. Therefore, it can be controlled by the program instructions of the NC machine tool, and the whole processing process is automatically carried out according to the program instructions.Can Mass Production Be Handled by CNC Machining? Without a doubt, the answer is yes! CNC machining is particularly good at accurately creating huge numbers of similar parts. CNC uses computer-controlled automation as opposed to human operation, which is the hallmark of traditional subtractive production methods.The impact of CNC production machining ranges from rapid prototyping to mass production, making it a valuable tool for businesses across a wide range of industries. 1.Excellence in Prototyping. One of the main benefits of CNC machining is its ability to produce high-precision prototypes. Design iterations are easily translated into tangible .

metal fabrication richmond va

Trace-A-Matic produces precision parts designed for high volume CNC machining while ensuring product quality. We have eight state-of-the-art facilities with 180+ machining centers, providing machining capacity tailored to the mass . Is CNC machining good for mass production? CNC machining is an excellent option for mass production due to its speed, accuracy, and consistency. CNC machines are capable of producing identical parts with precise .

Item Mame: Customized Metal Accessories CNC Machining Parts Surface: Anosized , Polishing Processing: CNC Machining, Milling, Turning, Lathe, Grind Package: Parts Use Foam Pack Outer Is Woox Box or Pallet Tolerace: +/-0.005mm Samples: First Do Samples Send Customer Test Introduction: In the manufacturing industry, selecting the right supplier for CNC machined parts is crucial for ensuring product quality, reducing production costs, and enhancing production efficiency. This becomes even more critical in scenarios requiring large-scale production, where the CNC machining capability and bulk production satisfaction of suppliers . Small Batch CNC (Computer Numerical Control) Machining is a manufacturing process that creates precise parts in smaller quantities, typically ranging from one to several hundred units. It’s a popular choice for prototypes, custom orders, or small production runs where high precision is needed. The process uses pre-programmed computer software to control the .

In the automotive industry, CNC machining has become an increasingly popular solution for producing high-quality and precise parts. From prototyping to mass production, CNC machining offers a range of benefits for automotive manufacturers, including flexibility in producing small quantities, the ability to produce complex geometries without the need for expensive . PMTS Founded in 2001, PMTS reconvenes in April 2025 to celebrate its 13th biennial event for precision machining pros. Mark your calendar now and plan to join the precision machined parts community when we once again gather in person to share challenges and insights, see new technology solutions and learn about process innovations – everything you .The machine is a Mori Seiki NL2500SY-700 CNC Turning Center with a Y-axis, C-axis on both spindles, live tooling, and a subspindle. Length 0:04:23 . If mass production, most of parts can be done by plastic injection molding or die casting if they are metal parts. You need to find a manufacturer who can support no moq like us. http://www.glacern.comhttp://twitter.com/glacernhttp://facebook.com/glacernhttp://vimeo.com/glacernGlacern Machine ToolsMass production turning of an aerospa.

metal fabrication schools near me

The importance of CNC machining stems from its ability to produce complex parts with tight tolerances and excellent surface finishes, making it indispensable in industries like aerospace, medical, automotive, and defense. . Beyond mass production, CNC machining also shines in custom applications and prototyping, offering engineers and .CNC machining may be among the oldest manufacturing technologies, but it is still widely used for making prototypes and end-use parts and products. Today, many companies can build a rapid prototype with CNC machining for the aerospace, automotive, sports, .This is where mass production, over molding, and CNC machining services play an essential role. Together, they form a dynamic trio that transforms raw materials into finished products through .

Mass Production

CNC drilling is a computer-controlled subtractive machining process, in which a rotating drill bit creates a round hole in a stationary workpiece (maybe wood, metal, plastic, or composite).

mass production cnc machining part|Production CNC Machining: Everything You Need to