how to insullate electrical boxes mn The Illustrated Field Guide to the Minnesota Residential Code, 2020 based on the 2018 edition of the Residential Code Essentials was developed to address the need for an illustrated text . Our concrete detention, retention, infiltration, treatment and harvesting solutions as well as custom concrete storm drain and conveyance product can meet your specific project needs. Oldcastle is the industry leader in proprietary storm water mansgement systems.

0 · How to Insulate around Electrical Boxes: A Step

1 · How To Insulate Electrical Outlets

2 · Foam Outlet Insulation Stops Cold Air Coming Through Electrical

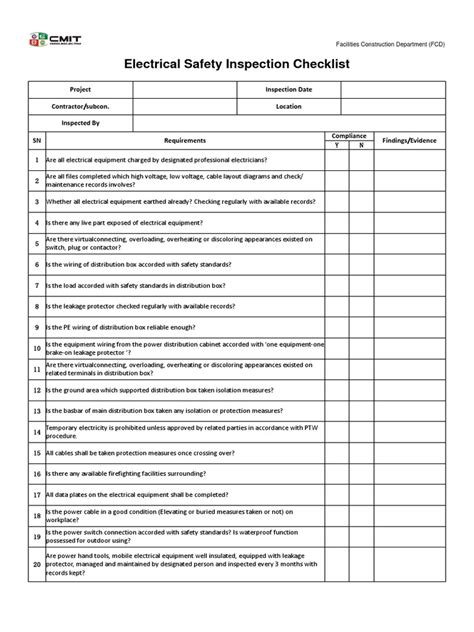

3 · Electrical inspection checklist for dwellings

4 · Electrical codes and standards

5 · Electrical Inspections Information Sheet

6 · Electrical Inspection Checklist for Single Family Dwellings

7 · Electrical Inspection Checklist for One

8 · An Easy Way to Seal Electrical Boxes

9 · Air

10 · 2020 Illustrated Field Guide to the Minnesota Residential Code

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc.

Underground wiring shall be inspected before the trench is back-filled. Except for the final connection to switches, receptacles, and lighting fixtures, all ground wires and other .The Minnesota Energy Code requires that all penetrations through an exterior air barrier be sealed. Sealing of the opening applies to all penetrations including the service-entrance, .The Illustrated Field Guide to the Minnesota Residential Code, 2020 based on the 2018 edition of the Residential Code Essentials was developed to address the need for an illustrated text .1. An electrical permit and electrical inspections are required for any electrical work associated with new construction, remodeling, replacement, or repair of electrical wiring, and equipment. .

Chapter 1315 of the Minnesota State Building Code adopts a national standard for the installation of electrical wiring, apparatus and equipment for electric light, heat, power, technology circuits . The process of insulating around electrical boxes involves a few simple steps including measuring the distance between the electrical box and the drywall, cutting and fitting the insulation, and sealing the insulation in place .

The foam seals the electrical box and insulates the space behind the box. Two architects have come up with an inexpensive way of air-sealing and insulating electrical boxes in exterior walls.Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations. Junction boxes (also known as electrical boxes, switch boxes, ceiling boxes, etc.) are designed to be a safe place for connections—junctions—between wires to take place. That way if you have a . They should be insulated behind if there is actually space back there. When I have panels changed I install a couple of studs with insulation and a piece of poly to the wall so the new plywood for the new panel can be mounted property and if the basement is ever finished in that area the basics are in place at the panel to do a decent job.

Rigid foam insulation: This can be used to insulate electrical boxes. These materials provide good thermal resistance and reduce heat conduction through structural elements. Polycarbonate: This is a common . The electrical box provides a secure and stable mounting point for your lighting fixture or ceiling fan. Follow these steps to install the ceiling electrical box: 1. Choose the right box: Select an electrical box that is appropriate for the size and .These will allow you to insulate tricky areas, and the foam will fill whatever voids you have -- perfect for pipes, around wiring, and around electrical boxes. Make sure you do not use these products in electrical boxes or around chimneys or other hot areas, as they are flammable. I believe it's OK to place insulation on top of junction boxes. Two architects have come up with an inexpensive way of air-sealing and insulating electrical boxes in exterior walls. After puzzling over the best way of meeting a code requirement for sealed boxes, Bill Hicks and Lucas Schad developed a cardboard form called the Box Shell that wraps around an electrical box. The form is slightly larger than the box, creating a small .

We recently installed new electrical boxes and hung fans from them. We caulked around the boxes to seal off airflow into the attic. There are several small holes (and one has a medium sized hole) on the boxes. What's the proper way to seal this off to prevent the blown-in insulation from falling through the hole into the box (a fire hazard I .

How to Insulate around Electrical Boxes: A Step

How To Insulate Electrical Outlets

The Family Handyman recommends using rigid foam, caulk, and spray foam to insulate the rim joist, in this article Insulate Basement Rim Joists. Not sure if this is exactly what you're looking to do, but the idea should work in your situation I think. Summary of steps: Cut rigid foam to fit between joists. Insert foam into gaps (against rim joist). There are 5 ways to soundproof electrical outlets and they are: Use acoustic putty; Fill the cavity around the outlet with mineral wool; Decouple the electrical outlet; Replace outlet with a soundproof outlet box; Fill the cavity around the outlet with acoustic caulk; When soundproofing electrical outlets, you’ll mainly be working to block .

Electrical boxes being buried in insulation aren’t specifically discussed in the NEC, so I turned to my second book, Electrical Inspections of Existing Dwellings, courtesy of the same folks at Code Check. Not only does this book have a lot of commentary and history of the electrical codes, but it’s written for home inspectors. It’s a book .

You can build a picture frame around the box - basically building the wall framing out enough that you can get a piece of foam insulating board on top of the back of the box. Even 1/2" of polyisocyanurate (R=3.2) plus the plywood sheathing and the sheetrock is going to give you less heat loss than that window the box is next to. 3. Lesco boxes create a wasted cavity/space around the electrical box that should be insulated on the outside wall and used for sound proofing when between interior walls. Electrical boxes and dead air spaces are high in the transmission of sound through the wall compared to other wall elements. Putty pads are dense and way better at sound . HOW TO steps for insulating Outlets Insulating Electrical Outlet Covers Insulate Electrical Outlets Insulate Outlets. Home Energy savings. Save heat and re.

Today I show you the easy steps to insulating your electrical outlets and switches. Plugs and switches located on outside walls of you home allow cold drafty. All the outlets on the exterior walls of the home can contribute to higher heating and cooling bills. The steps in this video show how to properly insulate e. For an electrical box, you set the depth of the wire blade to the depth for the electrical box. Remember, we still have drywall to add, so the depth is set in 1/2" to accommodate drywall. Step 3 Diagram

wires and boxes airtight electrical box caulked or taped to vapor retarder Wall insulation Fiberglass batts (below) can be applied if walls are opened to the interior. Care must be taken to not compress or leave voids in the insulation in order to maintain thermal performance. Penetrations (such as wires, electrical boxes, pipes) must be carefullyNo recessed lights, just the little junction boxes and electrical boxes that you would normally screw a light fixture into - as seen in the photo. The house is from 1870, so we've found a lot of other old wiring systems up there as well, but the house has been wired for a model 100A . systems up there as well, but the house has been wired for . When I spec electrical stuff, I strongly prefer to avoid putting any switchgear on the exterior, or even in unconditioned spaces like garages. The reason is that electrical equipment in unconditioned spaces tends to get condensation and dirt inside, and that causes deterioration of the connection points, which is a Bad Thing.

In this video, I show you the process for installing a vapor barrier around an electrical box. It is important to use a vapor barrier when installing an elec. Insulation acts as a sound barrier, absorbing noises that bounce off the floors and walls. Insulation reduces air leaks, keeping humidity levels low and reducing the growth of mold and mildew. Insulation can improve the indoor air quality by reducing the entry of .The electrical box designed for Insulated Concrete Form (ICF) construction. Insulating concrete forms (ICFs) is a method of construction using components manufactured from expanded polystyrene. The forms are constructed, reinforced with steel and then filled with concrete. Often used for the construction of hotels and schools, this method of . Look for switch/outlet insulators, like this one (Note: just the first one I found in a search, no recommendation of vendor or retailer implied.). It's a thin foam gasket designed to go under the cover plate to keep cold air from coming in through the box, but should do a reasonably good job of keeping much larger dust particles from getting into the box, too.

One of the more common locations for cold air leaks is around electrical outlets on exterior walls. Insulating electrical outlets with a foam gasket is an ea.

In this video, we show you a quick and easy way to install electrical boxes into ICF walls after they have been poured. Product Description Single gang electrical box for use with nonmetallic sheathed cable Brand: fiberglassBOX™ Catalog #: 9331-EK Height: 3-1/4 in. Width: 2-3/8 in. Depth: 2-1/2 in. Volume: 14 cu. in. Type of Installation:. Old Work Allied product link for the 2 .

Foam Outlet Insulation Stops Cold Air Coming Through Electrical

cnc lathe machine olx

Selecting the right electrical box for your project can be confusing because of the many options available. Whether you’re starting new construction or adding to existing wiring, understanding the different types of electrical .

how to insullate electrical boxes mn|Electrical Inspections Information Sheet