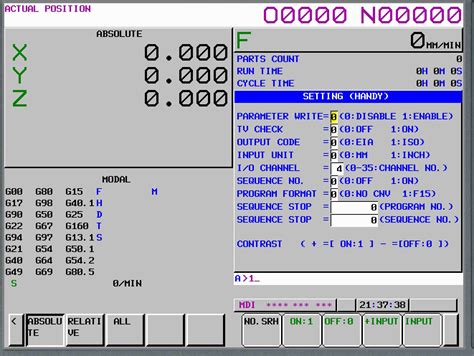

cnc machine tool parameters Figure 2 Z-axis tool setting parameters. The tool will back off in the +X direction, and in the process of backing off, the X-axis trial cutting positioning will be completed at the same time, as shown in Fig. 3 (a); after positioning, . The Original Slinky Brand Collector's Edition Metal Original Slinky Recommended for children 5 years of age and older . Black metal Slinky in a box inspired by the original 1945 release for an antique look. Perfect for stocking stuffers, prizes, presents, and .

0 · cnc parameters list

1 · cnc parameters explained

2 · cnc parameter settings

3 · cnc machining parameters list

4 · cnc machining parameters explained

5 · cnc cycle parameters

6 · best cnc parameters

7 · 7 cnc parameters

Valley Wide Sheet Metal, Inc. was founded in 1988. The company is located in Bermuda Dunes and incorporated in California. Valley Wide Sheet Metal, Inc. specializes in Sheet Metal Work, Nec. Receive a one-time comprehensive credit report on this company.

The main CNC machining parameters include cutting speed, spindle speed, feed rate, depth of cut, and others. Each of these parameters significantly impacts the machining process and the quality of the final product. Cutting Speed. Cutting speed is a critical .

A toolpath in CNC machining is the exact route that a cutting tool takes while it . The operation of CNC machining centers, despite their technological progress, can still be affected by undesirable events associated with the technological parameters of their operation. The minimization of these .

Figure 2 Z-axis tool setting parameters. The tool will back off in the +X direction, and in the process of backing off, the X-axis trial cutting positioning will be completed at the same time, as shown in Fig. 3 (a); after positioning, .

The selected tools on CNC machine tools often use tool materials suitable for high-speed cutting (such as high-speed steel, ultra-fine-grained cemented carbide) and use indexable inserts. 2. Choose tools for CNC turning . Feed speed is an important parameter in the cutting parameters of CNC machine tools, which is mainly selected according to . In modern manufacturing, CNC turn-mill machine tools are highly valued for their high precision and efficiency. However, to realize its full potential, processing parameters must be continually optimized to further improve production efficiency. This article will explore how to achieve this goal by optimizing the processing parameters of CNC turn-mill.Computer numerical control (CNC) machine tools are widely used in the manufacture of precision parts in aviation, aerospace and other fields due to their advantages of automation and precision (Liu et al., 2022a, 2022b, 2022c).With the continuous improvement of product quality requirements of users, it is very urgent to improve the machining accuracy of CNC machine tools.

Research on thermal characteristics modeling for feed system of CNC machine tool considering thermal parameter correction. Liang Peng, Zhenlei Chen [email protected], and Leilei Cheng View all authors and . Lin M. Thermal–mechanical coupling analysis and experimental study on CNC machine tool feed mechanism. Int J Precis Eng Manuf 2019; 20: .Acorn CNC12 Machine Configuration parameters: rev7 5-6-20 . Tool Turret Position Bit 1-4, refer to Tool Turret setup documentation. refer to Tool Turret setup . Set by Acorn Wizard, in CNC control preference menu. Bit wise. Choose Jogging preference on start up in Acorn Wizard. P857 : Z Following Options ***Currently Not Used*** P890 CNC machines can accommodate different types of tools, such as drills, end mills, and lathes, each with its own specific parameters. Optimizing the tool selection parameters is essential for achieving the desired finish and ensuring the longevity of the cutting tool.

Experimental results demonstrate that the proposed method can obtain accurate operational modal parameters for CNC machine tools. Conducting research on the dynamics of machine tools can prevent chatter during high-speed operation and reduce machine tool vibration, which is of significance in enhancing production efficiency. .Haas parameter list (mill/lathe) for cnc machinists who work on Haas cnc lathe/mill. Parameters are seldom-modified values that change the operation of the . Parameter SettingCentroid G10 Tool Offset Settings – CNC MillCentroid G10 Tool Offset Settings – CNC LatheCentroid G10 – Parameter SettingExamples:ExampleExample Centroid G10 . Machining process parameters (MPP) directly affect the machining quality and efficiency of heavy-duty CNC machine tools (HCMT). The selection of MPP is very important to effectively improve machining performance. Machining performance has been closely related to the HCMT running state. In order to maintain HCMT sustainably manufacturing with high . CNC machine tools wear diagnostic and prognostic by using dynamic Bayesian networks,” . Multiple attempts have been made to determine tool-wear parameters through offline and online diagnostics involving different techniques, namely operations research approaches, artificial intelligence (AI), CAD-based approaches. .

CNC machining center SCM Tech Z5. Table 1. Technical parameters of CNC machining center SCM Tech Z5. Technical Parameters of CNC Machining Center SCM Tech Z5 Useful desktop (mm) X = 3050, y = 1300 . Hello I have 2 small problems: 1.How can I read out/ change the radius and the length of a particular tool that is still in the magazine (so not in the spindle; of course with parameters in the program So I have to gain access to the radius and the lengths with particular parameters, but with what parameters? 2. How can I read out/change the radius and the .

cnc parameters list

Function Access: Function Description: Level 1 (93-3008) Level 2 (93-2905) Factory Tab: This Factory tab is located in the Diagnostics> Parameters.Here you will find a list of common Factory settings, like Tool Change Offsets, Spindle Orient Offsets, Grid Offsets, Autodoor Open Times, Disable Axes, Min/Max Coolant Level, Status Relays, Enable/Disable Chip . After an analysis of the effect of cutting parameters on excitation bandwidth and energy, the steps to estimate CNC machine-tool dynamic parameters through OMA are summed up. Section 3 presents the experimental verification of the method. The characteristics and feasibility of the proposed technique are discussed and compared with the impact . The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation . In order to reduce the effect of nonlinear friction and time-varying factors on the servo system of a computer numerical control (CNC) machine tool and improve its motion control accuracy, this paper uses an adaptive sliding mode control (ASMC) method based on model reference adaptive control (MRAC). The method adopts ASMC in the control outer loop and .

metal fabricator louisville louisville ky

The influence of the wireless communication on CNC machine tools touch-trigger probe inaccuracy of probing is investigated. Factors such as time of processing and wireless transmission of trigger signal from the probe to the CNC machine tool controller including position and orientation of the interface receiver are taken into consideration.Machine data and parameters Parameter Manual Valid for control SINUMERIK 840D sl / 840DE sl Software version CNC software 4.5 SP2 SINAMICS S120 4.5 03/2013 6FC5397-7AP40-3BA1 . 1.1 Explanation of the machine/setting data • Function Manual Tool Management, FBWsl

Here is the most comprehensive descriptive list of option parameters on the Fanuc O series controls. Please, if you have any details on additional option parameters leave what you know in the comments section at the end of the post.

metal fabricator corvallis corvallis or

cnc parameters explained

A calibration process of DMG Mori CNC machine Key Takeaways are: Understanding CNC Machine Structure: The structure of a CNC machine is complex, with several key components including the control software, drive system, linear guides and ball screws, spindle, tool length sensor, and coolant system. Each of these components plays a crucial role in the machine’s . Advanced CNC machines, especially in high-precision sectors, can achieve tolerances as tight as +/- 0.0005”. Conversely, older machines may only manage looser tolerances, highlighting the importance of using modern equipment for high-precision applications. . Process optimization, such as selecting durable tools and optimizing cutting . CNC machine tools and propose effective optimization methods to meet the manufacturing industry's demand for higher precision and performance. 2. Performance Analysis of Existing High-End CNC Machine Tools 2.1. Importance of High-End CNC Machine Tools High-end CNC machine tools hold exceptional imp. ortance in the field of modern manufacturing.

Since the beginning of China's industrialization process, the fault diagnosis of machine tools has always been a key research issue. Aiming at the problem of early failure of domestic CNC grinding machine, Li [1] divided early failure into sudden early failure and progressive early failure.The optimal fitting function was obtained by analyzing the machine .

Tool Shape; Metal Removal Rate; Specific Horsepower; Surface Finish. Chatter; Introduction. Cutting parameters are the changes in setup that affect the quality and efficiency of a cutting operation. Often, the optimum cutting parameter means finding the best balance between opposing factors. At its core, CNC machining is the automated control of machining tools and systems, including milling machines, CNC lathes, and grinders, by means of a computer. This manufacturing process transforms a digital model into a final part through successive material removal techniques. . Aggressive cutting parameters, improper machining tool .

cnc parameter settings

$44.99

cnc machine tool parameters|cnc parameter settings