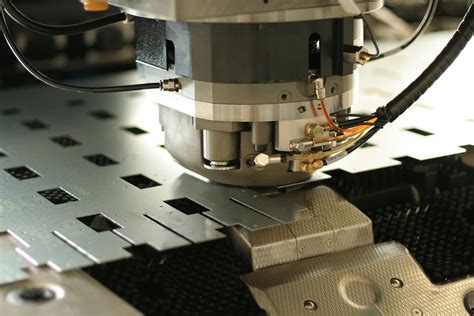

sheet metal shaping precision In practical terms, precision sheet metal fabrication relies on various techniques, including shaping, cutting, welding, and bending, often leveraging advanced technologies like computer numerical control (CNC).

Buy sheet metal parts in bulk online from 56 verified wholesale sheet metal parts suppliers, manufacturers (OEM, ODM & OBM), distributors, and factory lists on Global Sources.

0 · sheet metal stamping process

1 · sheet metal stamping

2 · sheet metal process

3 · sheet metal forming tools

4 · sheet metal forming techniques

5 · sheet metal forming process

6 · sheet metal forming

7 · sheet metal fabrication process

304 Stainless Steel Square Tube has inside and outside radius corners, with a protruding interior weld seam. Stainless Square Tube is ideal for all structural applications where greater strength and superior corrosion resistance is required.

After the precise cutting of metal sheets, the subsequent stage in sheet metal fabrication is the forming and shaping process. This phase is essential for giving the flat metal pieces their . Precision is a defining factor in sheet metal forming, as it directly influences the functionality, fit, and assembly of fabricated components. Achieving precise dimensions and geometries is essential for ensuring the optimal .

Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. This article will delve into the definition of sheet metal stamping, . From materials selection through shaping processes. Sheet metal forming can be seen as precise artistry that yields results of strength and endurance for all kinds of applications. Key Takeaways. Essential sheet metal . 1. A Beginner’s Guide to Swaging Machines: Perfecting Sheet Metal Shaping and Forming. In the realm of metalworking, where precision and artistry intertwine, the swaging .In practical terms, precision sheet metal fabrication relies on various techniques, including shaping, cutting, welding, and bending, often leveraging advanced technologies like computer numerical control (CNC).

Metal stamping stands as a cornerstone of modern manufacturing, offering a comprehensive and versatile set of techniques for shaping sheet metal into a vast array of precision parts.

Sheet metal fabrication involves precise engineering to transform stainless steel, carbon steel, and other materials into vital components for machinery and structures. This process includes bending, cutting, and .

CNC metal shaping is a versatile technique that allows for precise fabrication of various metal components. By utilizing multi-axis CNC machines, intricate metal shapes can be achieved with exceptional accuracy.We’ll cover everything from understanding precision in sheet metal to real-life examples of its applications, all while shedding light on current trends, innovative processes, and the advantages that precision manufacturing brings to various .Sheet metal fabrication is a versatile manufacturing process that involves shaping metal sheets through various techniques, such as laser cutting, stamping, and bending. Neway, a leading custom parts manufacturer, excels in sheet metal .

Superior quality precision sheet metal fabrication. Your expert partner in custom sheet metal fabrication. Request a Quote. Services. All your metal needs in one place. . The bending process refers to the operation of shaping flat sheets of metal into specific angles or curves. This is a critical step in the fabrication of various metal . Plate press machines operate on the principle of applying a controlled force to a metal sheet, causing it to deform and conform to the desired shape. This force is generated by a hydraulic or mechanical ram that descends upon the sheet, pressing it against a die or mold. . plate press machines play a vital role in shaping the world around us .

Sheet metal specialists recognize this responsibility and apply their expertise with the utmost care and diligence, never compromising on quality or safety. Repeatability and Consistency: Delivering Excellence Every Time. In the world of sheet metal fabrication, precision is not just a one-time achievement – it is a continuous pursuit.

We are committed to delivering precision-engineered solutions through our custom sheet metal fabrication services. Understanding the lifecycle of custom sheet metal fabrication is essential to appreciating the intricate processes and ensuring the highest quality outcomes. Our goal is to educate our clients and partners about each stage, from conceptualization to final . Precision sheet metal fabrication accurately produces detailed and ready-to-use parts for prototype to high-volume manufacturing with exact measurements. Services. . Cutting, CNC bending, and shaping. Use advanced methods like laser cutting and CNC machining. Materials: Wide range of metals, including steel, aluminum, brass, and copper.

With its ability to create complex shapes with high precision, CNC shaping has become a game-changer in various industries. Here is an overview of CNC shaping, highlighting its key features and benefits: . CNC metal shaping is a versatile technique that allows for precise fabrication of various metal components. By utilizing multi-axis CNC . Metal Stamping: Shaping Sheet Metal into Precision Parts. 2024-03-29. Metal stamping is a fundamental metalworking process that utilizes a press to transform flat sheet metal into a wide range of three-dimensional shapes. This technique plays a crucial role in numerous industries, enabling the mass production of various components with high .

Top 10 Metal Sheet Forming Machines for Precision Work: Shaping Metals with Surgical Precision. In the realm of metalworking, where raw material transforms into intricate masterpieces, precision metal sheet forming machines stand tall as the architects of form and function. These marvels of engineering wield the power to shape metal sheets with .Sheet metal stretch forming is a metal shaping process that involves stretching sheet metal over a form die. Stretch forming is key in aerospace sheet metal fabrication for creating strong, lightweight aircraft parts in complex shapes. With the bulldozer attachments on our Cyril Bath 800 ton stretch press, we can stretch form reverse forms. By .

sheet metal stamping process

5 Piece Forming T Dolly Set Form and Shape Metal with Precision. 4.0 out of 5 stars. 8. 4.99 $ 134. 99. FREE delivery Oct 1 - 3 . Seller . 9 Pcs Auto Body Panel Fender Hammer Dolly Set Sheet Metal Repair Tool Kit Dent Repair Tools Car Sheet Metal Shaping Movable Car Body Corrector Kit. 4.4 out of 5 stars. 13. .00 $ 72. 00. List: .99 . Borden Precision Products, Inc specializes in precision sheet metal fabrication. From electronic enclosures to finished surfaces we have the expertise to meet your production needs. The business was originally established in 1983, and has since been through many changes. In 2003, Chris Clayton took over ownership and operations of the company.Sheet Metal Metal Works. Metal form cutting, shaping and bending . Get a quote now! Enclosure & Cabinet Customized Cassette. Storing ideal for your manufacturing needs . . Our metal processing factory provides precision fabrication parts, sheet metal, jig and fixture. Altra Precision is also expertise in wire cutting, engineering design .We offer precision sheet metal forming for a variety of industrial needs. Metals must be precisely formed to satisfy your product specifications. . which begins when a flat blank of material is delivered from the material service center and extends through metal shaping, welding, powder coating, and assembly. Throughout this entire process .

A Plate Rolling machine built for Metal Shaping Sheet Metal Fabrication. Automation is becoming increasingly more important in metal shaping and in general. .At R&G Metal Shaping we offer CNC bending services for metals. CNC bending is an automated process whereby a computer controlled machine is used to bend and shape metal sheets and parts. This process allows us to produce high .Shaping Excellence in Metal Craftsmanship. CALL us FOR an ESTIMATE. 02 7257 6131. Superior Sheet Metal Works. Shaping Excellence in Metal Craftsmanship. Crafting Precision, Breathing Comfort: Superior Sheet Metal Works, where excellence meets every bend for unparalleled air conditioning ducts. Based in Ingleburn, NSW.These tools are specifically designed for sheet metal shaping tasks. When precision metal shaping is required, trust Picard's exceptional Bumping and Shaping Dollies and Spoons. Our tools offer a wider range of radius curves and unique shapes, surpassing other bumping tools available today. Experience the superior craftsmanship and .

Analysis and design: We have engineers and designers experienced in the analysis and design of parts, using state-of-the-art software to model and simulate the behaviour of the parts. Fabrication process: We have state-of-the-art machinery and advanced manufacturing techniques to ensure the quality and precision of the parts. Part Verification: We use high-precision 3D Laser . In the realm of metalworking, where steel meets precision, sheet metal press machines reign supreme. These colossal titans transform ordinary metal sheets into intricate components that underpin countless industries. . This perpetual innovation ensures that these machines remain at the forefront of metalworking, shaping the future with every .Sheet Metal 1 Learn with flashcards, games, and more — for free. . Precision sheet metal workers commonly fabricate and install gutters, sheet metal roofs, and louvers on new buildings. . Sheet metal fabrication involves cutting and shaping operations. True. Sheet metal is trimmed with squaring shears.

how much to replace an electrical panel box

Their ability to manipulate metal sheets with unparalleled precision unlocks a world of possibilities, shaping the future of industries from automotive to aerospace. The Art of Shaping Metal. Sheet metal rolling is an intricate process that involves passing a metal sheet between two or more cylindrical rollers.Discover the art of sheet metal design in this comprehensive guide. Learn fundamental principles, techniques, and prospects. . The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic . Referred to as forming, it is a technique that involves the reshaping or shaping of material to the desired outcome without material loss. Certain metals hold mechanical properties that permit plastic deformation from one form to another. . Precision sheet metal fabrication is a common manufacturing process that employs numerous applications .

CNC cutting – using computer programming software for precision sheet metal fabrication allows for even the most complex and intricate design to be achieved. Forming – the process of shaping sheet metal into a desired outcome is known as forming. Precision fabrication during the forming process ensures that structural integrity is not lost . Sheet metal fabrication involves cutting, bending, and shaping sheet metal to create custom parts or products. At our facility, we use state-of-the-art equipment and advanced techniques to ensure the highest level of precision and quality in every project we undertake. Sheet Metal Shaping with Metal Spinning Machine: Metal spinning, also known as spin forming or metal turning, is a process used to produce axially components . Precision: CNC metal spinning provides tighter tolerances for complex geometries, especially when creating parts with varying wall thicknesses. Roll forming is better suited for parts .

how to activate junction box in spider man

Stainless steel lunch boxes are being purchased and used by more and more households because they are beautiful, easy to clean, corrosion resistant and durable. As a stainless steel lunch box manufacturer, we have been designing .

sheet metal shaping precision|sheet metal forming techniques