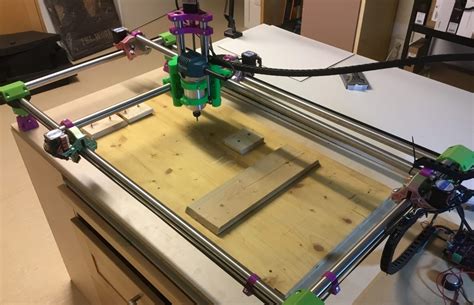

build a cnc machine I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine. Get yourself familiar with the concept of a CNC machine shop, its advantages, and how can you choose the best one for your machining needs!

0 · make your own cnc machine

1 · homemade cnc machine plans

2 · do it yourself cnc machine

3 · building your own cnc router

4 · building your own cnc machine

5 · build your own cnc mill

6 · build your own cnc

7 · build it yourself cnc router

A junction box makes that easier by allowing you to connect directly to the main breaker. This negates the need to running wire through the entire house back to the breaker, providing that the power requirements of those components .

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal .

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. The latest cnc machines are controlled via gcode and grbl, repetier, or Marlin based controllers. Using mach 4 is a bit like using Windows to set up a file server.

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.It will give you detailed instructions and provide clear high-resolution photos for each and every step. 3D models will make understanding the design much easier, and clearly documented Bills of Materials will allow you to order an exact amount of parts and start the build right away. Computer Numerical Control machines have revolutionized the manufacturing and hobbyist world. They offer precision, consistency, and automation to tasks that were previously manual and time-consuming. If you’re interested in crafting your very own CNC machine, you’ve come to the right place!

Building a CNC machine yourself offers several advantages: Cost Efficiency: Significantly lower cost compared to purchasing a commercial machine. Customization: Tailor the machine to specific needs and applications. Educational Value: Gain hands-on experience in mechanical engineering, electronics, and software integration.How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as well as size proved prohibitive.

To build a CNC machine, it's essential to have a solid understanding of how they work. In this section, we will explain the basic principles of CNC machines, including the role of stepper motors, linear motion systems, and control software. .

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. The latest cnc machines are controlled via gcode and grbl, repetier, or Marlin based controllers. Using mach 4 is a bit like using Windows to set up a file server.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.

make your own cnc machine

It will give you detailed instructions and provide clear high-resolution photos for each and every step. 3D models will make understanding the design much easier, and clearly documented Bills of Materials will allow you to order an exact amount of parts and start the build right away.

Computer Numerical Control machines have revolutionized the manufacturing and hobbyist world. They offer precision, consistency, and automation to tasks that were previously manual and time-consuming. If you’re interested in crafting your very own CNC machine, you’ve come to the right place! Building a CNC machine yourself offers several advantages: Cost Efficiency: Significantly lower cost compared to purchasing a commercial machine. Customization: Tailor the machine to specific needs and applications. Educational Value: Gain hands-on experience in mechanical engineering, electronics, and software integration.How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as well as size proved prohibitive.

homemade cnc machine plans

VI. Box Beams. The hollow rectangular shape of box beams gives an extraordinary strength-to-weight ratio. These adaptable structural pieces resist twisting and bending forces well which makes them good for high-stress uses. Box beams can handle load capacities up to 350 plf. They are used in industrial buildings, bridges and interior design.

build a cnc machine|building your own cnc machine