cnc machine programming g codes and m codes Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the .

Septic Tank Distribution Boxes & Drain Basins; Septic Tank Risers & Lids; Sump Pump Parts & Accessories; Heating; A.C. / Refrigeration Equipment; AIR SEPARATORS; AUTOMATIC AIR VENTS; Boiler Accessories; Circulating Pumps; Controls, Control Panels & Modules; Gas Burners; Gas-fired Boilers;

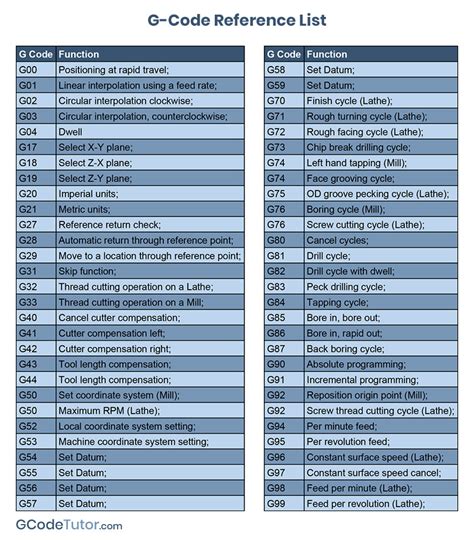

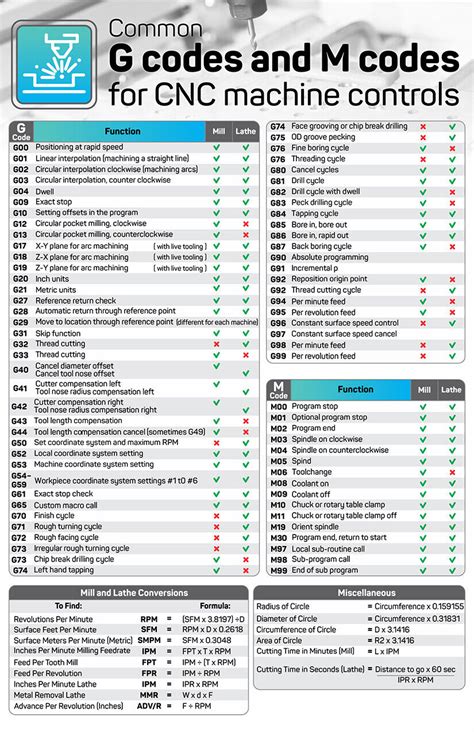

0 · g&m codes list

1 · g m codes cnc list

2 · g code m cheat sheet

3 · g code figure and table

4 · g code and m list

5 · g code and m chart

6 · g and m code sheet

7 · cnc g code and m list pdf

Discover refined junction boxes designed for efficient truck lighting systems. Discover high-quality parts for optimized lighting performance and durability.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)N10 G90 (Setting Absolute mode); N20 G00 X1.0 Y1.0 (Position the machine at [P1]); .

How to Apply G-codes relating to cutter compensation. Including Milling, .

4 | P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. . In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the .Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming.

g&m codes list

G-codes differ in different CNC machines, while M-codes are the same in most CNC machines. G-codes command the machine’s motion and function for the product’s design, while M-codes are used to conduct the non .

In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” . At the heart of CNC machining’s unmatched efficiency and accuracy are the G and M codes – the critical programming languages that guide CNC machines. Unlike common perception, G codes and M codes hold .

G and M codes are the building blocks of CNC programming. They are essentially the commands that instruct CNC machines to perform specific actions during the machining process. G-codes (also known as “geometric .

G-codes and M-codes serve distinct but complementary roles in controlling CNC machines. Here’s a summary of their key differences: G-code focuses on commands related to .

g m codes cnc list

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

4 | P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming.

G-codes differ in different CNC machines, while M-codes are the same in most CNC machines. G-codes command the machine’s motion and function for the product’s design, while M-codes are used to conduct the non-movement operations of the programming. In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool.

At the heart of CNC machining’s unmatched efficiency and accuracy are the G and M codes – the critical programming languages that guide CNC machines. Unlike common perception, G codes and M codes hold distinct roles in CNC operations. G and M codes are the building blocks of CNC programming. They are essentially the commands that instruct CNC machines to perform specific actions during the machining process. G-codes (also known as “geometric codes” or “preparatory codes”) define the movement and positioning of the cutting tool. G-codes and M-codes serve distinct but complementary roles in controlling CNC machines. Here’s a summary of their key differences: G-code focuses on commands related to tool movement, governing how the machine operates, including the cutting path and speed.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

g code m cheat sheet

4 | P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming. G-codes differ in different CNC machines, while M-codes are the same in most CNC machines. G-codes command the machine’s motion and function for the product’s design, while M-codes are used to conduct the non-movement operations of the programming. In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool.

At the heart of CNC machining’s unmatched efficiency and accuracy are the G and M codes – the critical programming languages that guide CNC machines. Unlike common perception, G codes and M codes hold distinct roles in CNC operations. G and M codes are the building blocks of CNC programming. They are essentially the commands that instruct CNC machines to perform specific actions during the machining process. G-codes (also known as “geometric codes” or “preparatory codes”) define the movement and positioning of the cutting tool.

clean cnc machine shop

clear lid electrical boxes

Tuf-Tite, Septic, Distribution Box, Drainage. CONTACT US. DRAWINGS. Sustainability. Tuf-Tite, Inc. Construction Products 1200 Flex Court Lake Zurich, IL 60047 800-382-7009 847-550-1011 . B1-Riser. Distribution and Drop Boxes. 7-Hole Dist. .

cnc machine programming g codes and m codes|g&m codes list