electro polishing sheet metal Achieve the highest-quality finish possible for your stainless steel, titanium, Nitinol, and other alloys with precise, repeatable results. Watch the video to learn more about Able's end-to-end metal finishing process.

Special Products & Mfg., Inc. has been serving growing OEM’s with manufacturing services and solutions for more than 50 years. We are a premier ISO 9001:2015 certified company specializing in precision sheet metal fabrication, electro-mechanical assembly, machining, welding, and powder coating.

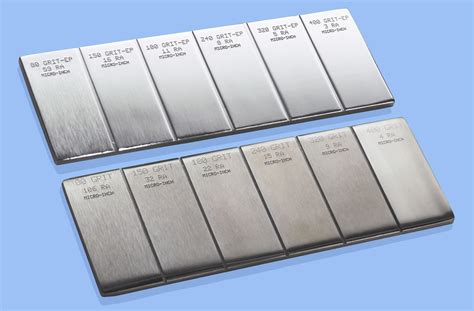

0 · electropolishing surface finish

1 · electropolishing stainless steel

2 · electropolishing products

3 · electropolishing metal

4 · electropolishing materials

5 · electropolishing aluminum

6 · electropolishing alloy

7 · electrolytic polishing

Advanced Metal and Welding specializes in designing, engineering, fabricating, and installing waste and scrap handling systems for industry, and is based in the Atlanta, Georgia metropolitan area.

Get a uniform, smooth, defects-free surface finish for metal and alloy parts with an electropolishing process. Insights on pros, cons, &applications.

Electropolishing removes metal from the micro peaks on a rough surface faster than it removes metal from recesses (anodic leveling). This reduces their height and makes the overall surface smoother. Targeted .Electropolishing, also known as electrochemical polishing, anodic polishing, or electrolytic polishing (especially in the metallography field), is an electrochemical process that removes material from a metallic workpiece, reducing the surface roughness by levelling micro-peaks and valleys, improving the surface finish. Electropolishing is often compared to, but distinctly different from, electrochemical machining. It is used to polish, passivate, and deburr metal parts. It is often descri.

Electropolishing is an electrochemical polishing process that removes surface imperfections including impurities, burrs, and other defects. .Electropolishing streamlines the microscopic surface of both the i.d. and o.d. of piping and tubing by removing the uppermost layer of the metal ion by ion, eliminating imperfections which trap and contain contaminants.

Achieve the highest-quality finish possible for your stainless steel, titanium, Nitinol, and other alloys with precise, repeatable results. Watch the video to learn more about Able's end-to-end metal finishing process. Get a uniform, smooth, defects-free surface finish for metal and alloy parts with an electropolishing process. Insights on pros, cons, &applications. Electropolishing removes metal from the micro peaks on a rough surface faster than it removes metal from recesses (anodic leveling). This reduces their height and makes the overall surface smoother. Targeted electropolishing can reduce surface roughness by up to 50%.Electropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part, typically stainless steel or similar alloys. The process leaves a shiny, smooth, ultra-clean surface finish.

Electropolishing, also known as electrochemical polishing, anodic polishing, or electrolytic polishing (especially in the metallography field), is an electrochemical process that removes material from a metallic workpiece, reducing the surface roughness by levelling micro-peaks and valleys, improving the surface finish.

Electropolishing is an electrochemical polishing process that removes surface imperfections including impurities, burrs, and other defects. The reverse plating process creates a smooth surface on metal objects that is microscopically featureless.Electropolishing streamlines the microscopic surface of both the i.d. and o.d. of piping and tubing by removing the uppermost layer of the metal ion by ion, eliminating imperfections which trap and contain contaminants.Achieve the highest-quality finish possible for your stainless steel, titanium, Nitinol, and other alloys with precise, repeatable results. Watch the video to learn more about Able's end-to-end metal finishing process.

Surface Enhancement: Electropolishing removes imperfections, burrs, and contaminants from metal parts, resulting in a smooth, clean, and high-gloss finish. This enhanced surface is not only visually appealing but also improves functionality.

Electropolishing is an electrochemical process that is used to remove material at a controlled rate from the surface of stainless steel. Electropolishing improves microscopic imperfections, enhances aesthetics, deburrs parts, and makes parts easier to clean. When applied to the ID of pipe system components used in high-purity and ultrahigh-purity applications, electropolishing helps to achieve and maintain the necessary cleanness. While conventional mechanical finishing processes are macro metal removal processes, electropolishing is a micro process. Get a uniform, smooth, defects-free surface finish for metal and alloy parts with an electropolishing process. Insights on pros, cons, &applications. Electropolishing removes metal from the micro peaks on a rough surface faster than it removes metal from recesses (anodic leveling). This reduces their height and makes the overall surface smoother. Targeted electropolishing can reduce surface roughness by up to 50%.

Electropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part, typically stainless steel or similar alloys. The process leaves a shiny, smooth, ultra-clean surface finish.Electropolishing, also known as electrochemical polishing, anodic polishing, or electrolytic polishing (especially in the metallography field), is an electrochemical process that removes material from a metallic workpiece, reducing the surface roughness by levelling micro-peaks and valleys, improving the surface finish.Electropolishing is an electrochemical polishing process that removes surface imperfections including impurities, burrs, and other defects. The reverse plating process creates a smooth surface on metal objects that is microscopically featureless.

corrugated roofing sheets metal

Electropolishing streamlines the microscopic surface of both the i.d. and o.d. of piping and tubing by removing the uppermost layer of the metal ion by ion, eliminating imperfections which trap and contain contaminants.Achieve the highest-quality finish possible for your stainless steel, titanium, Nitinol, and other alloys with precise, repeatable results. Watch the video to learn more about Able's end-to-end metal finishing process.Surface Enhancement: Electropolishing removes imperfections, burrs, and contaminants from metal parts, resulting in a smooth, clean, and high-gloss finish. This enhanced surface is not only visually appealing but also improves functionality.Electropolishing is an electrochemical process that is used to remove material at a controlled rate from the surface of stainless steel. Electropolishing improves microscopic imperfections, enhances aesthetics, deburrs parts, and makes parts easier to clean.

electropolishing surface finish

Welding sheet metal with a wire feed welder involves preparation, precision, and proper technique to achieve strong, clean welds. From selecting the right equipment to finishing the weld, each step plays a crucial role in the process.

electro polishing sheet metal|electropolishing products