sheet metal general tolerances The following charts give typical ASTM and ANSI steel sheet mechanical tolerance . Waterproof Electrical Junction Box IP67 ABS Plastic Enclosure with Hinged Cover with Mounting Plate, Wall Brackets, Cable Glands (Off-white, 5.9"x5.9"x3.5") 4.8 out of 5 stars 870

0 · typical sheet metal tolerances

1 · standard sheet metal tolerances chart

2 · sheet metal tolerances chart

3 · sheet metal thickness tolerance chart

4 · sheet metal stamping tolerances

5 · sheet metal bending tolerance standard

6 · ses d 2101 standard pdf

7 · is 2102 tolerance chart

Shop online for wholesale aluminium 6061? Global Sources has a full-scale list of wholesale aluminium 6061 products at factory prices featured by verified wholesalers & manufacturers from China, India, Korea, and other countries to satisfy all the requirements!

Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered .

Sheet Metal & Wire Gauge Sizes Data Chart. Tolerances, Engineering Design .

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .You should define tolerance class as per design requirements and manufacturing capability. For example, the manufacturer recommends ISO 2768-mk for sheet metal parts and ISO 2768-fh .We follow many standards in the world of sheet metal fabrication. ISO 2768 is the most commonly used standard for tolerances in general, while ANSI Y14.5 is more specific. These standards are a guideline that ensures consistency in .

What Is Sheet Metal Tolerance? Sheet metal tolerance refers to the specified range that allows for deviations in the design sizes of parts. This range defines the upper and . Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from .ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). It applies for the linear . Protolabs Sheet Metal Tolerances. We break out tolerances into two categories. Tolerances on one surface; Tolerances across multiple surfaces; Tolerances on one surface are much tighter than those across multiple .

typical sheet metal tolerances

The sheet metal parameters are dependent on the machines & tooling that will be used to bend the parts, which is far from universal between different manufacturers. 3D files - this is the closest to a “universal part” that you will .TSZ2202G General Tolerances - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides standards for dimensional tolerances of parts formed from sheet metal through press working. It . Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from dimensional deviations to angular tolerances. By the end, you’ll grasp the importance of these tolerances and how .

standard sheet metal tolerances chart

For part sizes without marked tolerance ranges, this standard should be followed. Please note that all tolerance limits are given in mm. Part 1: General Tolerances ISO 2768-1. ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). This whitepaper helps describe a set of broad guidelines that you can use while specifying tolerances for your sheet metal parts drawing(s). Essentially, these are in place due to practical limitations of sheet metal forming, shearing and punching. Please note that these tolerances can change from manufacturer to manufacturer and this is .

GENERAL TOLERANCES FOR FORM AND POSITION (DIN ISO 2768 T2) STRAIGHTNESS AND FLATNESS Ranges in nominal Tolerance class lengths in mm H K L up to 10 0.02 0.05 0.1 over 10 up to 30 0.05 0.1 0.2 over 30 up to 100 0.1 0.2 0.4 over 100 up to 300 0.2 0.4 0.8 over 300 up to 1000 0.3 0.6 1.2 over 1000 up to 3000 0.4 0.8 1.6In sheet metal design, I would not be designing where I would require 15mil tolerance for anything to line up correctly. That's why god invented slotted holes. . I'm used to +/-.030" as the standard tolerance for bent sheet metal parts without really thinking about it. Tighter can be achieved, so +/-.015" seems reasonable if that's what you .

Sheet Metal Guage Tolerances During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.IS 2102-1 (1993): General tolerances, Part 1: Tolerances for linear and angular dimensions without individual tolerance indications [PGD 20: Engineering Standards] . removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. 3 Parallel International Standards exist or .To maintain general tolerances in sheet metal fabrication, several best practices can be followed: 1. Material Selection: Choose the appropriate material for the specific fabrication process and desired tolerances. This may involve consulting with material suppliers or conducting material testing to determine the best material for the job.

Tolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ).1) All manufacturing tolerances used up to that point (such as laser-cutting tolerances, welding tolerances and more) 2) All bend tolerances for the entire part, added together We call this an uncontrolled dimensions because there are additional tolerances to consider. The ISO 2768 series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular. Skip to content. Call Us: +86-0755-2998-8842 | Email: [email protected]. ISO 9001/ISO 13485/ISO 14001 Certified . including CNC machining, sheet metal fabrication, custom tooling .

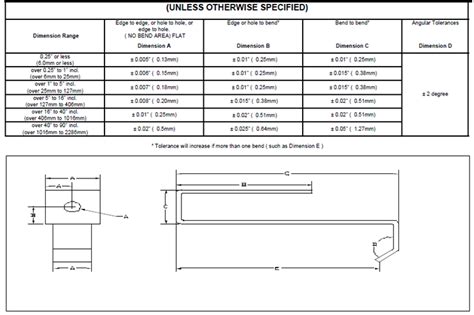

Factors Influencing General Tolerances in Sheet Metal Fabrication . Several factors can influence the general tolerances in sheet metal fabrication. These include: 1. Material properties:Different materials have different properties that can affect tolerances, such as hardness, ductility, and thermal expansion. It is essential to understand the . The main thing to be considered for selection of sheet metal tolerance is not just the Linear dimension as like IS 2102, the Reference from where to where the dimension take plays a vital role. Table 3.1 shown the .General tolerances, also known as default tolerances, title block tolerances, or Unless Otherwise Specified (UOS) tolerances, are standard tolerances for dimensional variation applied when specific tolerances aren’t explicitly stated on an engineering drawing.These tolerances provide a default level of precision, establishing acceptable ranges for part dimensions without requiring .

cnc machine monitoring system market

EF-001 Recommended Default Sheet Metal Tolerances Rev A Recommended Default Sheet Metal Tolerances Default Tolerances (Millimeters) DIM Tolerance Description A ± 0.13 Sheared Edge to Hole B ± 0.13 2 Holes on One Surface C ± 0.25 Formed Edge to Hole D* ± 0.76 Holes Across 2 Bends E* ± 0.76 Holes Across 4 Bends

ISO 2768 is an important standard for general tolerances in sheet metal fabrication. It specifies tolerance classes for linear dimensions, angular dimensions (ISO 2768-1) and geometrical tolerances (ISO 2768-2). The standard has four tolerance classes: fine (f), medium (m), coarse (c), and very coarse (v). . Sheet metal tolerances describe the allowable variations in shape, size, and geometry for sheet metal fabrication. Metal tolerancing impacts project outcomes in multiple ways, including fit, functionality, manufacturing costs, and performance. Teams designing high-quality interchangeable parts require tight tolerances for better integration and . Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . In general, when the hole diameter is less than the material thickness the pierce point will often cause the hole to be out of tolerance. 3D Feature Constraints: .

Tolerance class is defined as per design requirements and manufacturing capability. For example : for sheet metal parts ISO 2768–mk is used. And for machined components ISO 2768–fh can be used. ISO 2768-2 : 1989, General tolerances — Part 2: Geometrical tolerances for features without individual tolerance indications. ISO 8015 : 1985

Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about .This post is to help you understand what the holdable tolerance can be for your sheet metal parts. However even for an experienced designer, it may be difficult and time-consuming to decide the tolerances for each and every dimension, an easier approach is to explain to the manufacturer or DFM engineer how the part fits and functions in the assembly, how it interacts with the mating .

Sheet metal Tolerance Standrards, welding Tolerance Standards, General Tolerance Standards, IS 2102 Tolerance details, V groove pulley material Sheet Metal Tolerance Standards This blog discusses in over view of How to select sheet metal Tolerance as .

The main thing to be considered for selection of sheet metal tolerance is not just the Linear dimension as like IS 2102, the Reference from where to where the dimension take plays a vital role. Table 3.1 shown the unspecified Sheet metal Tolerance. For edge to edge, hole to hole & edge to hole, tolerances shall be taken from column A

sheet metal tolerances chart

Whole house water filters help keep sediments, harsh chemicals and smells out of your home. What a filter prevents from entering your water can vary, so it’s important to find a filter.

sheet metal general tolerances|ses d 2101 standard pdf