conduit electrical boxe sizes Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. Mounting an electrical box to metal studs requires self-drilling screws. This includes installing the electrical system inside of the metal framed wall. The electrical components may look similar, but electrical components designed .

0 · underground electrical pull box sizes

1 · pull box standard sizes

2 · pull box sizing chart

3 · nec box sizing chart

4 · junction box sizes chart

5 · electrical pull box sizes

6 · electrical pull box size chart

7 · electrical box sizing chart

Sheet metal is typically sold in three different forms: mild steel, aluminum, and stainless steel. The first two are the most widely used for car restorations. Here is a close look at the differences between these three types of sheet metals and the benefits of each one.

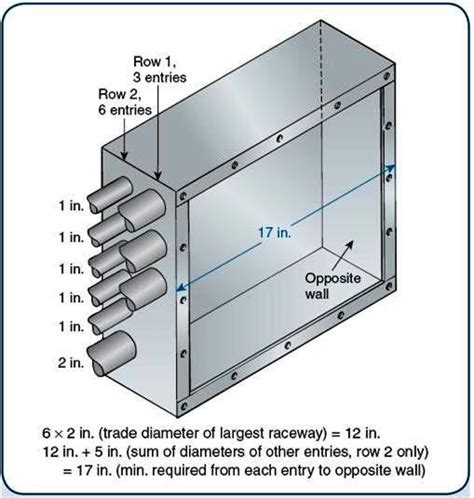

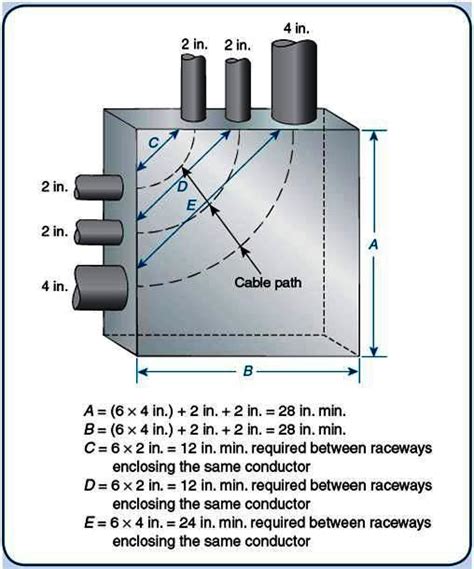

The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).

You must size pull boxes, junction boxes, and conduit bodies large enough so a .

underground electrical pull box sizes

pull box standard sizes

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For .Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to .Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill .

Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances .314.17 (B) Boxes and Conduit Bodies. Code Change Summary: Revised code section on the installation requirements for conductors in boxes and conduit bodies. In the 2020 NEC ®, the requirements previously found in 314.17 (B) .The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in .Boxes come in various sizes, usually categorized by their volume or capacity, which is typically measured in cubic inches (CI). Here are some considerations when choosing the right size: Number of Conductors: Consider the number of .

Specify the size of each conduit in inches. Select whether the pull is a straight pull or an angle pull. Click the “Calculate” button to obtain the minimum size of the pull box. The calculator . The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ). Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value.

Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.314.17 (B) Boxes and Conduit Bodies. Code Change Summary: Revised code section on the installation requirements for conductors in boxes and conduit bodies. In the 2020 NEC ®, the requirements previously found in 314.17 (B) and (C) were combined into .The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull.Boxes come in various sizes, usually categorized by their volume or capacity, which is typically measured in cubic inches (CI). Here are some considerations when choosing the right size: Number of Conductors: Consider the number of wires .

pull box sizing chart

Specify the size of each conduit in inches. Select whether the pull is a straight pull or an angle pull. Click the “Calculate” button to obtain the minimum size of the pull box. The calculator employs the following rules based on the NEC standards: The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ). Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value.

Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.

314.17 (B) Boxes and Conduit Bodies. Code Change Summary: Revised code section on the installation requirements for conductors in boxes and conduit bodies. In the 2020 NEC ®, the requirements previously found in 314.17 (B) and (C) were combined into .The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull.Boxes come in various sizes, usually categorized by their volume or capacity, which is typically measured in cubic inches (CI). Here are some considerations when choosing the right size: Number of Conductors: Consider the number of wires .

nec box sizing chart

junction box sizes chart

electrical pull box sizes

electrical pull box size chart

The ideal size of hole saw for a round electrical box is 3 inches in diameter. This size allows for a secure fit of standard electrical junction boxes. A properly sized hole ensures that the box is held securely and allows for safe electrical connections.

conduit electrical boxe sizes|electrical pull box size chart