6 metal stud box header Guide on how to frame metal stud headers (cold-formed steel). Check out the differences, pros, and cons between different styles of header. plate. Devices are recessed 3 1/4" [83mm] below floor surface. No cover assembly is included. For use with the following cover assemblies (purchased separately): 6CTC and 6CT series. .

0 · metal stud size chart

1 · metal stud door header detail

2 · metal stud box header detail

3 · metal framing size chart

4 · metal box header span chart

5 · light gauge steel header chart

6 · exterior metal stud wall details

7 · exterior metal stud framing details

This article describes how to wire a simple on-off electric light switch, how to wire 3-way light switches to control lights from two locations, and how to wire 4-way light switches to control lights (or other devices) from three or more locations.

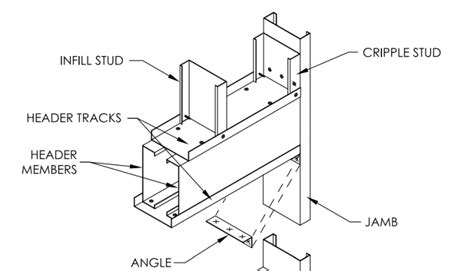

Boxed jamb studs welded together reduces material build-up and finish problems. Use of cripple stud to receive head/sill tracks at the jamb studs helps maintain alignment of finishes. Back to . Guide on how to frame metal stud headers (cold-formed steel). Check out the differences, pros, and cons between different styles of header.6″ stud with 1-5/8″ legs, 43 mils thick standard G60 coating (G90 available upon special request for an additional cost and possible extended lead-time). Easily create a submittal by selecting the components which apply to your specific . The Heavy-Duty Stud (HDS®) Framing System is a high .

In steel framing the primary header type used is a box header. The American Iron and Steel Institute did a great deep dive into box beam design and web stiffeners. There are two types of headers: L headers and Box Headers.The superior strength and carrying capacity of the HDS means higher performance with fewer members. It eliminates box beam headers, stud-to-track nesting, built-up members for posts and jambs and has superior axial strength .

RedHeader PRO™ can cut your labor time in half. It’s designed to replace conventional boxed headers and built-up jambs and provide better results in half the time. One-piece headers and jambs eliminate the additional studs, track .

The SHH steel header hanger is used to support traditional CFS box headers that are fabricated with top and bottom tracks, as well as large-flange lay-in headers that are common in curtain-wall construction. There are two types of headers, L headers, and Box Headers. They discuss the advantages of each one starting on page 32. I like the attached file below for a table on how to size metal stud headers. See page 79 where how to size header spans begin.Boxed jamb studs welded together reduces material build-up and finish problems. Use of cripple stud to receive head/sill tracks at the jamb studs helps maintain alignment of finishes. Back to back header reduces web-crippling reinforcement requirements. Guide on how to frame metal stud headers (cold-formed steel). Check out the differences, pros, and cons between different styles of header.

6″ stud with 1-5/8″ legs, 43 mils thick standard G60 coating (G90 available upon special request for an additional cost and possible extended lead-time). Easily create a submittal by selecting the components which apply to your specific project materials list.The Heavy-Duty Stud (HDS®) Framing System is a high-performance, cost effective, multi-purpose, heavy-duty framing stud for headers, jambs, posts and built-up tube truss chords and webs. The superior strength and carrying capacity of the HDS means higher performance with fewer members. In steel framing the primary header type used is a box header. The American Iron and Steel Institute did a great deep dive into box beam design and web stiffeners. There are two types of headers: L headers and Box Headers.The superior strength and carrying capacity of the HDS means higher performance with fewer members. It eliminates box beam headers, stud-to-track nesting, built-up members for posts and jambs and has superior axial strength for load-bearing projects.

RedHeader PRO™ can cut your labor time in half. It’s designed to replace conventional boxed headers and built-up jambs and provide better results in half the time. One-piece headers and jambs eliminate the additional studs, track and screws required to .

The SHH steel header hanger is used to support traditional CFS box headers that are fabricated with top and bottom tracks, as well as large-flange lay-in headers that are common in curtain-wall construction.M I L L C E R T I F I E D 1 0 0 % EG A L V A N I Z D COLD-FORMED STEEL FRAMING DETAILS 2014 www.SCAFCO.com Priceless HDR Header & Kwik-Jamb System PLC3 Bypass Slab Slide Clip There are two types of headers, L headers, and Box Headers. They discuss the advantages of each one starting on page 32. I like the attached file below for a table on how to size metal stud headers. See page 79 where how to size header spans begin.Boxed jamb studs welded together reduces material build-up and finish problems. Use of cripple stud to receive head/sill tracks at the jamb studs helps maintain alignment of finishes. Back to back header reduces web-crippling reinforcement requirements.

Guide on how to frame metal stud headers (cold-formed steel). Check out the differences, pros, and cons between different styles of header.6″ stud with 1-5/8″ legs, 43 mils thick standard G60 coating (G90 available upon special request for an additional cost and possible extended lead-time). Easily create a submittal by selecting the components which apply to your specific project materials list.The Heavy-Duty Stud (HDS®) Framing System is a high-performance, cost effective, multi-purpose, heavy-duty framing stud for headers, jambs, posts and built-up tube truss chords and webs. The superior strength and carrying capacity of the HDS means higher performance with fewer members. In steel framing the primary header type used is a box header. The American Iron and Steel Institute did a great deep dive into box beam design and web stiffeners. There are two types of headers: L headers and Box Headers.

The superior strength and carrying capacity of the HDS means higher performance with fewer members. It eliminates box beam headers, stud-to-track nesting, built-up members for posts and jambs and has superior axial strength for load-bearing projects.RedHeader PRO™ can cut your labor time in half. It’s designed to replace conventional boxed headers and built-up jambs and provide better results in half the time. One-piece headers and jambs eliminate the additional studs, track and screws required to .

The SHH steel header hanger is used to support traditional CFS box headers that are fabricated with top and bottom tracks, as well as large-flange lay-in headers that are common in curtain-wall construction.

add power from junction box

metal stud size chart

metal stud door header detail

$21.23

6 metal stud box header|light gauge steel header chart